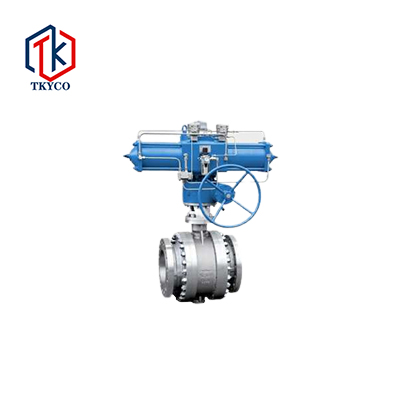

Metaalsitplek-kogelklep

Produkbeskrywing

Die aandrywingsgedeelte van die klep volgens die klepstruktuur en gebruikersvereistes, met behulp van handvatsel, turbine, elektries, pneumaties, ens., kan gebaseer word op die werklike situasie en gebruikersvereistes om die toepaslike aandrywingsmodus te kies.

Hierdie reeks kogelklepprodukte volgens die situasie van die medium en pyplyn, en die verskillende vereistes van gebruikers, ontwerp van brandvoorkoming, anti-statiese, soos struktuur, weerstand teen hoë temperatuur en lae temperatuur kan verseker dat kleppe onder verskillende toestande dikwels werk, wyd gebruik in natuurlike gas, olie, chemiese industrie, metallurgie, stedelike konstruksie, omgewingsbeskerming, farmaseutiese, voedsel en ander nywerhede.

Kenmerke

• Die reekskleppe gebruik smeedstaal of gietstaal as hul rompmateriaal. Die struktuur kan drywende tipe of taptipe balstutte wees.

• Hoë-presisie-bewerking lei tot superieure bal- en sitplek-koppelvlak vir 'n digte afsluiting wat voldoen aan die lekkasiestandaard van ANSI B16.104 dans VI.

• Vloeirigting vir die drywende gemonteerde tipe is unidireksioneel. Die trunnion-gemonteerde tipe is volledig bidireksioneel met dubbel-blok-en-bloei-vermoë.

• Betroubare werking met lae bedryfsmoment: Die diafragma-veerbelaaide sitplek handhaaf noue kontak met die bal en verseker 'n digte verseëling, selfs teen lae druk. Dit lei tot lae oop- en toemaakmomente.

• Brandveilig: Die kombinasie van metaalsitplekke en grafietseëls verseker brandveilige vermoëns.

• Die hoogste dienstoepassingstemperature is tot 550°C (1022°F). Die bal en sitplek word verhard deur ruimtevlug-hoëspoed-oorlegsel. En die hardheid voldoen aan HRC 70-72.

• Eindverbindings: DIN- of ANSI-flens, stomplas of soklas.

Drywende Tipe Dimensies

| Klepgrootte | GB | L | ΦD | ΦD1 | Nh | GB | L | ΦD | ΦD1 | Nh | GB | L | ΦD | ΦD1 | Nh | GB | L | ΦD | ΦD1 | Nh |

| 15 (1/2) | 16 | 130 | 95 | 65 | 4-14 | 25 | 130 | 95 | 65 | 4-14 | 40 | 130 | 95 | 65 | 4-14 | 64 | 165 | 105 | 75 | 4-14 |

| 20 (3/4) | 140 | 105 | 75 | 4-14 | 140 | 105 | 75 | 4-14 | 140 | 105 | 75 | 4-14 | 190 | 130 | 90 | 4-14 | ||||

| 25(1) | 140 | 115 | 85 | 4-14 | 140 | 115 | 85 | 4-14 | 150 | 115 | 85 | 4-14 | 216 | 140 | 100 | 4-14 | ||||

| 32 (1 1/4) | 165 | 140 | 100 | 4-18 | 165 | 140 | 100 | 4-18 | 180 | 140 | 100 | 4-18 | 229 | 155 | 110 | 4-22 | ||||

| 40 (1 1/2) | 165 | 150 | 110 | 4-18 | 165 | 150 | 110 | 4-18 | 200 | 150 | 110 | 4-18 | 241 | 170 | 125 | 4-22 | ||||

| 50(2) | 203 | 165 | 125 | 4-18 | 203 | 165 | 125 | 4-18 | 220 | 165 | 125 | 4-18 | 292 | 180 | 135 | 4-22 | ||||

| 65 (2 1/2) | 222 | 185 | 145 | 8-18 | 222 | 185 | 145 | 8-18 | 250 | 185 | 145 | 8-18 | 330 | 205 | 160 | 8-22 | ||||

| 80(3) | 241 | 200 | 160 | 8-18 | 241 | 200 | 160 | 8-18 | 280 | 200 | 160 | 8-18 | 356 | 215 | 170 | 8-22 | ||||

| 100 (4) | 280 | 220 | 180 | 8-18 | 280 | 235 | 190 | 8-22 | 320 | 235 | 190 | 4-22 | 432 | 250 | 200 | 8-26 | ||||

| 125 (5) | 320 | 250 | 210 | 8-18 | 320 | 270 | 220 | 8-26 | 400 | 270 | 220 | 8-26 | 508 | 295 | 240 | 8-30 | ||||

| 150 (6) | 360 | 285 | 240 | 4-22 | 360 | 300 | 250 | 8-26 | 400 | 300 | 250 | 8-26 | 559 | 345 | 280 | 8-33 | ||||

| 200 (8) | 457 | 340 | 295 | 12-22 | 457 | 360 | 310 | 12-22 | 457 | 375 | 320 | 12-30 | 660 | 400 | 345 | 12-36 |

| Klepgrootte | ANSI | L | ΦD | ΦD1 | Nh | ANSI | L | ΦD | ΦD1 | Nh | ANSI | L | ΦD | ΦD1 | Nh | JISK | L | ΦD | ΦD1 | Nh |

| 15 (1/2) | 150 | 108 | 90 | 60.3 | 4-16 | 300 | 140 | 95 | 66.7 | 4-16 | 600 | 165 | 95 | 66.7 | 4-16 | 10K | 108 | 95 | 70 | 4-15 |

| 20 (3/4) | 117 | 100 | 69.9 | 4-16 | 152 | 115 | 82.6 | 4-19 | 190 | 115 | 82.6 | 4-19 | 117 | 100 | 75 | 4-15 | ||||

| 25(1) | 127 | 110 | 79.4 | 4-16 | 165 | 125 | 88.9 | 4-19 | 216 | 125 | 88.9 | 4-19 | 127 | 125 | 90 | 4-19 | ||||

| 32 (1 1/4) | 140 | 115 | 88.9 | 4-16 | 178 | 135 | 98.4 | 4-19 | 229 | 135 | 98.4 | 4-19 | 140 | 135 | 100 | 4-19 | ||||

| 40 (1 1/2) | 165 | 125 | 98.4 | 4-16 | 190 | 155 | 114.3 | 4-22.5 | 241 | 155 | 114.3 | 4-22.5 | 165 | 140 | 105 | 4-19 | ||||

| 50(2) | 178 | 150 | 120.7 | 4-19 | 216 | 165 | 127 | 8-19 | 292 | 165 | 127 | 8-19 | 178 | 155 | 120 | 4-19 | ||||

| 65 (2 1/2) | 190 | 180 | 139.7 | 4-19 | 241 | 190 | 149.2 | 8-22.5 | 330 | 190 | 149.2 | 8-22.5 | 190 | 175 | 140 | 4-19 | ||||

| 80(3) | 203 | 190 | 152.4 | 4-19 | 282 | 210 | 168.3 | 8-22.5 | 356 | 210 | 168.3 | 8-22.5 | 203 | 185 | 150 | 8-19 | ||||

| 100 (4) | 229 | 230 | 190.5 | 8-19 | 305 | 255 | 200 | 8-22.5 | 432 | 275 | 215.9 | 8-25.5 | 229 | 210 | 175 | 8-19 | ||||

| 125 (5) | 356 | 255 | 215.9 | 8-22.5 | 381 | 280 | 235 | 8-22.5 | 508 | 330 | 266.7 | 8-30 | 356 | 250 | 210 | 8-23 | ||||

| 150(6) | 394 | 280 | 241.3 | 8-22.5 | 403 | 320 | 269.9 | 12-22.5 | 559 | 355 | 292.1 | 12-30 | 394 | 280 | 240 | 8-23 | ||||

| 200 (8) | 457 | 345 | 298.5 | 8-22.5 | 502 | 380 | 330.2 | 12-25.5 | 660 | 420 | 349.2 | 12-33 | 457 | 330 | 290 | 12-23 |

GB

| DN | L | PN16 | D | D1 | D2 | b | f | n-Φd | PN25 | D | D1 | D2 | b | f | n-Φd | PN40 | L | D | D1 | D2 | b | f | n-Φd |

| 100 | 305 | 220 | 180 | 158 | 20 | 2 | 8-18 | 235 | 190 | 158 | 24 | 2 | 8-22 | 305 | 235 | 190 | 162 | 24 | 2 | 8-22 | |||

| 125 | 356 | 250 | 210 | 188 | 22 | 2 | 8-18 | 270 | 220 | 188 | 26 | 2 | 8-26 | 381 | 270 | 220 | 188 | 26 | 2 | 8-26 | |||

| 150 | 394 | 285 | 240 | 212 | 22 | 2 | 8-22 | 300 | 250 | 218 | 28 | 2 | 8-26 | 403 | 300 | 250 | 210 | 28 | 2 | 8-26 | |||

| 200 | 457 | 340 | 295 | 268 | 24 | 2 | 12-22 | 360 | 310 | 278 | 30 | 2 | 12-26 | 502 | 375 | 320 | 285 | 34 | 2 | 12-30 | |||

| 250 | 533 | 405 | 355 | 320 | 26 | 2 | 12-26 | 425 | 370 | 335 | 32 | 2 | 12-30 | 568 | 450 | 385 | 345 | 38 | 2 | 12-33 | |||

| 300 | 610 | 460 | 410 | 378 | 28 | 2 | 12-26 | 485 | 430 | 395 | 34 | 2 | 16-30 | 648 | 515 | 450 | 410 | 42 | 2 | 16-33 | |||

| 350 | 686 | 520 | 470 | 428 | 30 | 2 | 16-26 | 555 | 490 | 450 | 38 | 2 | 16-33 | 762 | 580 | 510 | 465 | 46 | 2 | 16-36 | |||

| 400 | 762 | 580 | 525 | 490 | 32 | 2 | 16-30 | 620 | 550 | 505 | 40 | 2 | 16-36 | 838 | 660 | 585 | 535 | 50 | 2 | 16-39 | |||

| 450 | 864 | 640 | 585 | 550 | 40 | 2 | 20-30 | 670 | 600 | 555 | 46 | 2 | 20-36 | 914 | 685 | 610 | 560 | 57 | 2 | 20-39 |

ANSI

| in | DN | L | 150 pond | D | D1 | D2 | b | f | n-Φd | 300 pond | D | D1 | D2 | b | f | n-Φd | 600 pond | L | D | D1 | D2 | b | f | n-Φd |

| 4″ | 100 | 305 | 230 | 190.5 | 157.2 | 24 | 2 | 8-19 | 255 | 200 | 157.2 | 32 | 2 | 8-22 | 432 | 275 | 215.9 | 157.2 | 45.1 | 7 | 8-26 | |||

| 5″ | 125 | 356 | 255 | 215.9 | 185.7 | 24 | 2 | 8-22 | 280 | 235 | 185.7 | 35 | 2 | 8-22 | 508 | 330 | 266.7 | 185.7 | 51.5 | 7 | 8-30 | |||

| 6″ | 150 | 394 | 280 | 241.3 | 215.9 | 26 | 2 | 8-22 | 320 | 269.9 | 215.9 | 37 | 2 | 12-22 | 559 | 355 | 292.1 | 215.9 | 54.7 | 7 | 12-30 | |||

| 8″ | 200 | 457 | 345 | 298.5 | 269.9 | 29 | 2 | 8-22 | 380 | 330.2 | 269.9 | 42 | 2 | 12-25 | 660 | 420 | 349.2 | 269.9 | 62.6 | 7 | 12-33 | |||

| 10″ | 250 | 533 | 405 | 362 | 323.8 | 31 | 2 | 12-25 | 445 | 387.4 | 323.8 | 48 | 2 | 16-29 | 787 | 510 | 431.8 | 323.8 | 70.5 | 7 | 16-36 | |||

| 12″ | 300 | 610 | 485 | 431.8 | 381 | 32 | 2 | 12-25 | 520 | 450.8 | 381 | 51.5 | 2 | 16-32 | 838 | 560 | 489 | 381 | 73.7 | 7 | 20-36 | |||

| 14″ | 350 | 686 | 535 | 476.3 | 412.8 | 35.5 | 2 | 12-29 | 585 | 514.4 | 412.8 | 54.5 | 2 | 20-32 | 889 | 605 | 527 | 412.8 | 76.9 | 7 | 20-39 | |||

| 16″ | 400 | 762 | 595 | 539.8 | 469.9 | 37 | 2 | 16-29 | 650 | 571.5 | 469.9 | 57.5 | 2 | 20-35 | 991 | 685 | 603.2 | 469.9 | 83.2 | 7 | 20-42 | |||

| 18″ | 450 | 864 | 635 | 577.9 | 533.4 | 40 | 2 | 16-30 | 710 | 628.6 | 533.4 | 61 | 2 | 24-35 | 1092 | 745 | 654 | 533.4 | 89.6 | 7 | 20-45 |

JIS

| DN | L | 10K | D | D1 | D2 | b | f | n-Φd | 20K | D | D1 | D2 | b | f | n-Φd |

| 100A | 305 | 210 | 175 | 151 | 18 | 2 | 8-19 | 225 | 185 | 160 | 24 | 2 | 8-23 | ||

| 125A | 356 | 250 | 210 | 182 | 20 | 2 | 8-23 | 270 | 225 | 195 | 26 | 2 | 8-25 | ||

| 150A | 394 | 280 | 240 | 212 | 22 | 2 | 8-23 | 305 | 260 | 230 | 28 | 2 | 12-25 | ||

| 200A | 457 | 330 | 290 | 262 | 22 | 2 | 12-23 | 350 | 305 | 275 | 30 | 2 | 12-25 | ||

| 250A | 533 | 400 | 355 | 324 | 24 | 2 | 12-25 | 430 | 380 | 345 | 34 | 3 | 12-27 | ||

| 300A | 610 | 445 | 400 | 368 | 24 | 3 | 16-25 | 480 | 430 | 395 | 36 | 3 | 16-27 | ||

| 350A | 686 | 490 | 445 | 413 | 26 | 3 | 16-25 | 540 | 480 | 440 | 40 | 3 | 16-33 | ||

| 400A | 762 | 560 | 510 | 475 | 28 | 3 | 16-27 | 605 | 540 | 495 | 46 | 3 | 16-33 | ||

| 450A | 864 | 620 | 565 | 530 | 30 | 3 | 20-27 | 675 | 605 | 560 | 48 | 3 | 20-33 |