Metalen sitbalklep

Produktbeskriuwing

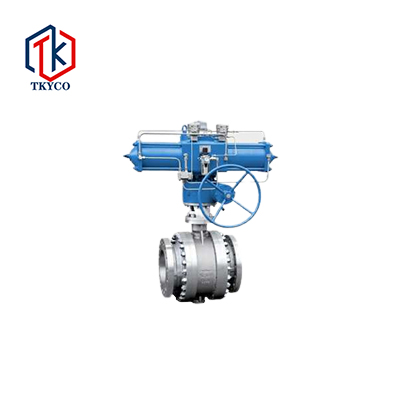

It driuwende diel fan 'e fentyl neffens de fentylstruktuer en brûkerseasken, mei help fan handgreep, turbine, elektrysk, pneumatyske, ensfh., kin basearre wurde op 'e werklike situaasje en brûkerseasken om de passende rydmodus te kiezen.

Dizze searje kûgelkleppen kinne, neffens de situaasje fan it medium en de piiplieding, en de ferskillende easken fan brûkers, it ûntwerp fan brânprevinsje, anty-statysk, lykas struktuer, wjerstân tsjin hege en lege temperatueren, derfoar soargje dat de kleppen ûnder ferskate omstannichheden faak wurkje, en wurde in soad brûkt yn ierdgas, oalje, gemyske yndustry, metallurgy, stedsbou, miljeubeskerming, farmaseutyske, iten en oare yndustryen.

Funksjes

• De searjekleppen brûke smeid stiel of getten stiel as lichemsmateriaal. De struktuer kin driuwend type of trunnion-type kogelstipes wêze.

• Hege presyzje-bewerking resultearret yn superieure bal- en sit-ynterface foar in tichte ôfsluting dy't foldocht oan de lekkagestandert fan ANSI B16.104 dans VI.

• De streamrjochting foar it driuwend monteard type is unidireksjoneel. It trunnion-monteard type is folslein bidireksjoneel mei dûbele blokkearring en ûntluchting.

• Betroubere operaasjes mei leech wurkkoppel: De membraanfearbelaste sit hâldt nau kontakt mei de bal en soarget foar in goede ôfsluting, sels by lege druk. Dit resulteart yn lege iepenings- en slutingskoppels.

• Brânfeilich: De kombinaasje fan metalen sitten en grafytdichtingen soarget foar brânfeilige mooglikheden.

• De heechste temperatueren foar tsjinsttapassingen binne oant 550 °C (1022 °F). De bal en sit binne ferhurde troch in hege-snelheidsoverlay yn romtefeart. En de hurdens foldocht oan HRC 70-72.

• Einferbiningen: DIN- of ANSI-flens, stomplas of moflas.

Ofmjittings fan driuwende type

| Klepgrutte | GB | L | ΦD | ΦD1 | Nh | GB | L | ΦD | ΦD1 | Nh | GB | L | ΦD | ΦD1 | Nh | GB | L | ΦD | ΦD1 | Nh |

| 15 (1/2) | 16 | 130 | 95 | 65 | 4-14 | 25 | 130 | 95 | 65 | 4-14 | 40 | 130 | 95 | 65 | 4-14 | 64 | 165 | 105 | 75 | 4-14 |

| 20 (3/4) | 140 | 105 | 75 | 4-14 | 140 | 105 | 75 | 4-14 | 140 | 105 | 75 | 4-14 | 190 | 130 | 90 | 4-14 | ||||

| 25(1) | 140 | 115 | 85 | 4-14 | 140 | 115 | 85 | 4-14 | 150 | 115 | 85 | 4-14 | 216 | 140 | 100 | 4-14 | ||||

| 32 (1 1/4) | 165 | 140 | 100 | 4-18 | 165 | 140 | 100 | 4-18 | 180 | 140 | 100 | 4-18 | 229 | 155 | 110 | 4-22 | ||||

| 40 (1 1/2) | 165 | 150 | 110 | 4-18 | 165 | 150 | 110 | 4-18 | 200 | 150 | 110 | 4-18 | 241 | 170 | 125 | 4-22 | ||||

| 50(2) | 203 | 165 | 125 | 4-18 | 203 | 165 | 125 | 4-18 | 220 | 165 | 125 | 4-18 | 292 | 180 | 135 | 4-22 | ||||

| 65 (2 1/2) | 222 | 185 | 145 | 8-18 | 222 | 185 | 145 | 8-18 | 250 | 185 | 145 | 8-18 | 330 | 205 | 160 | 8-22 | ||||

| 80(3) | 241 | 200 | 160 | 8-18 | 241 | 200 | 160 | 8-18 | 280 | 200 | 160 | 8-18 | 356 | 215 | 170 | 8-22 | ||||

| 100 (4) | 280 | 220 | 180 | 8-18 | 280 | 235 | 190 | 8-22 | 320 | 235 | 190 | 4-22 | 432 | 250 | 200 | 8-26 | ||||

| 125 (5) | 320 | 250 | 210 | 8-18 | 320 | 270 | 220 | 8-26 | 400 | 270 | 220 | 8-26 | 508 | 295 | 240 | 8-30 | ||||

| 150 (6) | 360 | 285 | 240 | 4-22 | 360 | 300 | 250 | 8-26 | 400 | 300 | 250 | 8-26 | 559 | 345 | 280 | 8-33 | ||||

| 200 (8) | 457 | 340 | 295 | 12-22 | 457 | 360 | 310 | 12-22 | 457 | 375 | 320 | 12-30 | 660 | 400 | 345 | 12-36 |

| Klepgrutte | ANSI | L | ΦD | ΦD1 | Nh | ANSI | L | ΦD | ΦD1 | Nh | ANSI | L | ΦD | ΦD1 | Nh | JISK | L | ΦD | ΦD1 | Nh |

| 15 (1/2) | 150 | 108 | 90 | 60.3 | 4-16 | 300 | 140 | 95 | 66.7 | 4-16 | 600 | 165 | 95 | 66.7 | 4-16 | 10K | 108 | 95 | 70 | 4-15 |

| 20 (3/4) | 117 | 100 | 69.9 | 4-16 | 152 | 115 | 82.6 | 4-19 | 190 | 115 | 82.6 | 4-19 | 117 | 100 | 75 | 4-15 | ||||

| 25(1) | 127 | 110 | 79.4 | 4-16 | 165 | 125 | 88.9 | 4-19 | 216 | 125 | 88.9 | 4-19 | 127 | 125 | 90 | 4-19 | ||||

| 32 (1 1/4) | 140 | 115 | 88.9 | 4-16 | 178 | 135 | 98.4 | 4-19 | 229 | 135 | 98.4 | 4-19 | 140 | 135 | 100 | 4-19 | ||||

| 40 (1 1/2) | 165 | 125 | 98.4 | 4-16 | 190 | 155 | 114.3 | 4-22.5 | 241 | 155 | 114.3 | 4-22.5 | 165 | 140 | 105 | 4-19 | ||||

| 50(2) | 178 | 150 | 120.7 | 4-19 | 216 | 165 | 127 | 8-19 | 292 | 165 | 127 | 8-19 | 178 | 155 | 120 | 4-19 | ||||

| 65 (2 1/2) | 190 | 180 | 139.7 | 4-19 | 241 | 190 | 149.2 | 8-22.5 | 330 | 190 | 149.2 | 8-22.5 | 190 | 175 | 140 | 4-19 | ||||

| 80(3) | 203 | 190 | 152.4 | 4-19 | 282 | 210 | 168.3 | 8-22.5 | 356 | 210 | 168.3 | 8-22.5 | 203 | 185 | 150 | 8-19 | ||||

| 100 (4) | 229 | 230 | 190.5 | 8-19 | 305 | 255 | 200 | 8-22.5 | 432 | 275 | 215.9 | 8-25.5 | 229 | 210 | 175 | 8-19 | ||||

| 125 (5) | 356 | 255 | 215.9 | 8-22.5 | 381 | 280 | 235 | 8-22.5 | 508 | 330 | 266.7 | 8-30 | 356 | 250 | 210 | 8-23 | ||||

| 150(6) | 394 | 280 | 241.3 | 8-22.5 | 403 | 320 | 269.9 | 12-22.5 | 559 | 355 | 292.1 | 12-30 | 394 | 280 | 240 | 8-23 | ||||

| 200 (8) | 457 | 345 | 298.5 | 8-22.5 | 502 | 380 | 330.2 | 12-25.5 | 660 | 420 | 349.2 | 12-33 | 457 | 330 | 290 | 12-23 |

GB

| DN | L | PN16 | D | D1 | D2 | b | f | n-Φd | PN25 | D | D1 | D2 | b | f | n-Φd | PN40 | L | D | D1 | D2 | b | f | n-Φd |

| 100 | 305 | 220 | 180 | 158 | 20 | 2 | 8-18 | 235 | 190 | 158 | 24 | 2 | 8-22 | 305 | 235 | 190 | 162 | 24 | 2 | 8-22 | |||

| 125 | 356 | 250 | 210 | 188 | 22 | 2 | 8-18 | 270 | 220 | 188 | 26 | 2 | 8-26 | 381 | 270 | 220 | 188 | 26 | 2 | 8-26 | |||

| 150 | 394 | 285 | 240 | 212 | 22 | 2 | 8-22 | 300 | 250 | 218 | 28 | 2 | 8-26 | 403 | 300 | 250 | 210 | 28 | 2 | 8-26 | |||

| 200 | 457 | 340 | 295 | 268 | 24 | 2 | 12-22 | 360 | 310 | 278 | 30 | 2 | 12-26 | 502 | 375 | 320 | 285 | 34 | 2 | 12-30 | |||

| 250 | 533 | 405 | 355 | 320 | 26 | 2 | 12-26 | 425 | 370 | 335 | 32 | 2 | 12-30 | 568 | 450 | 385 | 345 | 38 | 2 | 12-33 | |||

| 300 | 610 | 460 | 410 | 378 | 28 | 2 | 12-26 | 485 | 430 | 395 | 34 | 2 | 16-30 | 648 | 515 | 450 | 410 | 42 | 2 | 16-33 | |||

| 350 | 686 | 520 | 470 | 428 | 30 | 2 | 16-26 | 555 | 490 | 450 | 38 | 2 | 16-33 | 762 | 580 | 510 | 465 | 46 | 2 | 16-36 | |||

| 400 | 762 | 580 | 525 | 490 | 32 | 2 | 16-30 | 620 | 550 | 505 | 40 | 2 | 16-36 | 838 | 660 | 585 | 535 | 50 | 2 | 16-39 | |||

| 450 | 864 | 640 | 585 | 550 | 40 | 2 | 20-30 | 670 | 600 | 555 | 46 | 2 | 20-36 | 914 | 685 | 610 | 560 | 57 | 2 | 20-39 |

ANSI

| in | DN | L | 150 pûn | D | D1 | D2 | b | f | n-Φd | 300 pûn | D | D1 | D2 | b | f | n-Φd | 600 pûn | L | D | D1 | D2 | b | f | n-Φd |

| 4″ | 100 | 305 | 230 | 190.5 | 157.2 | 24 | 2 | 8-19 | 255 | 200 | 157.2 | 32 | 2 | 8-22 | 432 | 275 | 215.9 | 157.2 | 45.1 | 7 | 8-26 | |||

| 5″ | 125 | 356 | 255 | 215.9 | 185.7 | 24 | 2 | 8-22 | 280 | 235 | 185.7 | 35 | 2 | 8-22 | 508 | 330 | 266.7 | 185.7 | 51.5 | 7 | 8-30 | |||

| 6″ | 150 | 394 | 280 | 241.3 | 215.9 | 26 | 2 | 8-22 | 320 | 269.9 | 215.9 | 37 | 2 | 12-22 | 559 | 355 | 292.1 | 215.9 | 54.7 | 7 | 12-30 | |||

| 8″ | 200 | 457 | 345 | 298.5 | 269.9 | 29 | 2 | 8-22 | 380 | 330.2 | 269.9 | 42 | 2 | 12-25 | 660 | 420 | 349.2 | 269.9 | 62.6 | 7 | 12-33 | |||

| 10″ | 250 | 533 | 405 | 362 | 323.8 | 31 | 2 | 12-25 | 445 | 387.4 | 323.8 | 48 | 2 | 16-29 | 787 | 510 | 431.8 | 323.8 | 70.5 | 7 | 16-36 | |||

| 12″ | 300 | 610 | 485 | 431.8 | 381 | 32 | 2 | 12-25 | 520 | 450.8 | 381 | 51.5 | 2 | 16-32 | 838 | 560 | 489 | 381 | 73.7 | 7 | 20-36 | |||

| 14″ | 350 | 686 | 535 | 476.3 | 412.8 | 35.5 | 2 | 12-29 | 585 | 514.4 | 412.8 | 54.5 | 2 | 20-32 | 889 | 605 | 527 | 412.8 | 76.9 | 7 | 20-39 | |||

| 16″ | 400 | 762 | 595 | 539.8 | 469.9 | 37 | 2 | 16-29 | 650 | 571.5 | 469.9 | 57.5 | 2 | 20-35 | 991 | 685 | 603.2 | 469.9 | 83.2 | 7 | 20-42 | |||

| 18″ | 450 | 864 | 635 | 577.9 | 533.4 | 40 | 2 | 16-30 | 710 | 628.6 | 533.4 | 61 | 2 | 24-35 | 1092 | 745 | 654 | 533.4 | 89.6 | 7 | 20-45 |

JIS

| DN | L | 10K | D | D1 | D2 | b | f | n-Φd | 20K | D | D1 | D2 | b | f | n-Φd |

| 100A | 305 | 210 | 175 | 151 | 18 | 2 | 8-19 | 225 | 185 | 160 | 24 | 2 | 8-23 | ||

| 125A | 356 | 250 | 210 | 182 | 20 | 2 | 8-23 | 270 | 225 | 195 | 26 | 2 | 8-25 | ||

| 150A | 394 | 280 | 240 | 212 | 22 | 2 | 8-23 | 305 | 260 | 230 | 28 | 2 | 12-25 | ||

| 200A | 457 | 330 | 290 | 262 | 22 | 2 | 12-23 | 350 | 305 | 275 | 30 | 2 | 12-25 | ||

| 250A | 533 | 400 | 355 | 324 | 24 | 2 | 12-25 | 430 | 380 | 345 | 34 | 3 | 12-27 | ||

| 300A | 610 | 445 | 400 | 368 | 24 | 3 | 16-25 | 480 | 430 | 395 | 36 | 3 | 16-27 | ||

| 350A | 686 | 490 | 445 | 413 | 26 | 3 | 16-25 | 540 | 480 | 440 | 40 | 3 | 16-33 | ||

| 400A | 762 | 560 | 510 | 475 | 28 | 3 | 16-27 | 605 | 540 | 495 | 46 | 3 | 16-33 | ||

| 450A | 864 | 620 | 565 | 530 | 30 | 3 | 20-27 | 675 | 605 | 560 | 48 | 3 | 20-33 |