At Controls Butterfly Valve: Top Manufacturer in China for Quality Solutions

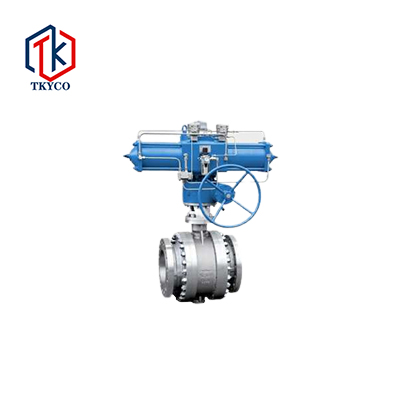

When it comes to reliable fluid control, At Controls Butterfly Valve stands out as a top choice for industries around the globe. As a manufacturer based in China, we pride ourselves on delivering valves that ensure precision and durability. Our butterfly valves are designed for easy operation and maintenance, making them ideal for various applications, from HVAC systems to wastewater management. I understand the importance of quality and efficiency in your operations. That’s why our valves undergo strict testing to meet international standards, giving you confidence in their performance. Whether you're sourcing components for a new project or seeking replacements for existing systems, our butterfly valves offer the reliability you need. With a focus on innovation and customer satisfaction, we strive to provide exceptional service and support to our clients. Partner with us to experience the benefits of high-quality valve solutions tailored to meet your specific requirements. Trust At Controls to help you streamline your processes and maximize your operational efficiency.

At Controls Butterfly Valve Where Innovation Meets 2025 Service Backed by Expertise

In the ever-evolving world of industrial solutions, the need for reliable and innovative products is paramount. As we navigate through 2025, one of the cornerstones of efficiency and quality in flow control is the butterfly valve. These valves offer a unique blend of performance and versatility, making them ideal for a myriad of applications across industries ranging from oil and gas to water treatment. Our commitment to persistence and excellence ensures that every valve meets rigorous standards, reflecting our dedication to quality and innovation. What sets our butterfly valves apart is not merely their design, but the extensive expertise that backs their development and service. Our seasoned team works tirelessly to ensure that each valve is engineered with precision and longevity in mind. Moreover, we understand that global procurement dynamics are constantly changing, and thus, we provide tailored solutions that cater to the specific needs of our clients. Our support doesn't end at the sale; it extends into comprehensive after-sales service, guiding users through maintenance and operational challenges, ensuring that their systems run smoothly and efficiently. Choosing the right butterfly valve is crucial for enhancing operational reliability and efficiency. By leveraging cutting-edge technology and embracing innovation, we empower our clients to make informed decisions that significantly impact their business performance. As we move into 2025, we invite global buyers to explore the unparalleled benefits of our butterfly valves—where performance meets expertise and an unwavering commitment to service. Together, we can foster sustainable growth and redefine industry standards.

At Controls Butterfly Valve Where Innovation Meets 2025 Service Backed by Expertise

| Dimension | Specification | Material | Application | Service Life |

|---|---|---|---|---|

| 2" (50 mm) | Class 150 | Cast Iron | Water Treatment | 10+ years |

| 4" (100 mm) | Class 300 | Stainless Steel | Chemical Processing | 15 years |

| 6" (150 mm) | Class 150 | PVC | HVAC Systems | 8 years |

| 8" (200 mm) | Class 150 | Aluminum | Oil & Gas | 12 years |

| 10" (250 mm) | Class 300 | Brass | Fire Protection | 20 years |

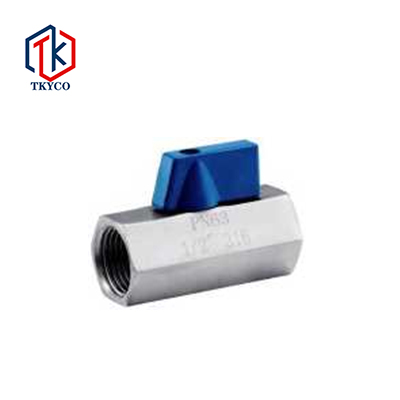

Related Products