Ball Valve

-

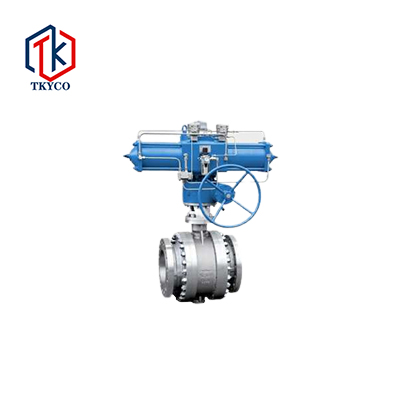

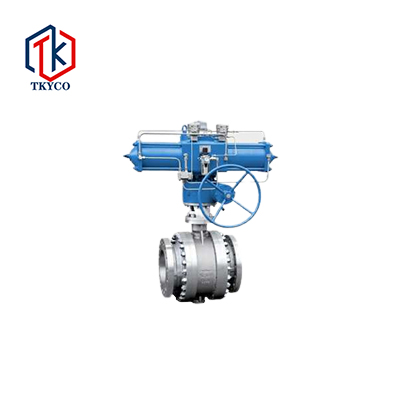

METAL SEAT (FORGED) BALL VALVE

Product Overview Forged steel flange type high pressure ball valve closing parts of the ball around the center line of the valve body for rotation to open and close a valve, the seal is embedded in the stainless steel valve seat, the metal valve seat is provided with a spring, when the sealing surface wear or burn, under the action of the spring to push the valve seat and the ball to form a metal seal.Exhibit unique automatic pressure release function, when the valve lumen medium pressure mor... -

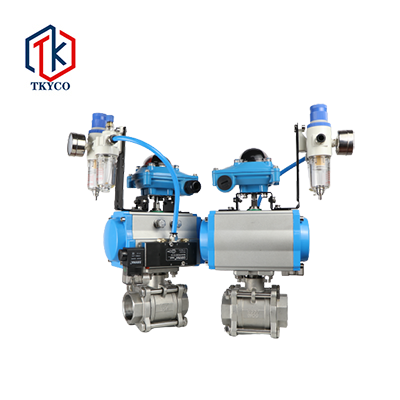

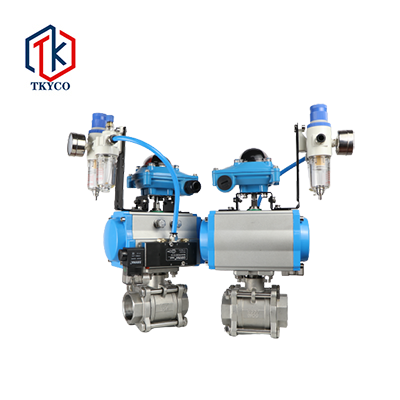

Pneumatic, Electric Actuator, Thread, Sanitary Clamped Ball Valve

Specifications

Nominal pressure: PN1.6-6.4, Class150/300,10k/20k

• Strength testing pressure: PT1.5PN

• Seat testing pressure(low pressure): 0.6MPa• Applicable temperature: -29°C-150°C

• Applicable media:

Q6 11/61F-(16-64)C Water. Oil. Gas

Q6 11/61F-(16-64)P Nitric acid

Q6 11/61F-(16-64)R Acetic acid -

ANSI Floating Flange Ball Valve

Design standards

Technical specification: ANSI

• Design standard: API6D API608

• Structure length: ASME B16.10

• Connection flange: ASME B16.5

-Test and Inspection: API6D API598Performance Specification

• Nominal pressure: 150, 300, 600 LB

-Strength test: PT3.0, 7.5,15 Mpa

• Seal test: 2.2, 5.5,11 Mpa

• Gas seal test: 0.6Mpa

-The valve main material: WCB (C), CF8 (P), CF3 (PL), CF8M (R), CF3M (RL)

• Suitable medium: water, steam, oil products, nitric acid, acetic acid

-Suitable temperature: -29°C -150°C -

Pneumatic Flange Ball Valve

Performance Specification

-Nominal pressure: PN1.6-6.4 Class 150/300, 10k/20k

• Strength testing pressure: PT1.5PN

• Seat testing pressure(low pressure): 0.6MPa

• Applicable media:

Q641F-(16-64)C Water. Oil. Gas

Q641F-(16-64)P Nitric acid

Q641F-(16-64)R Acetic acid

• Applicable temperature: -29°C-150°C -

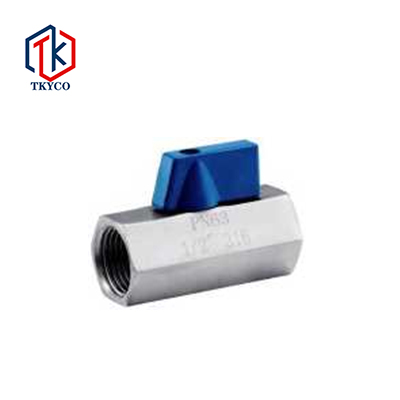

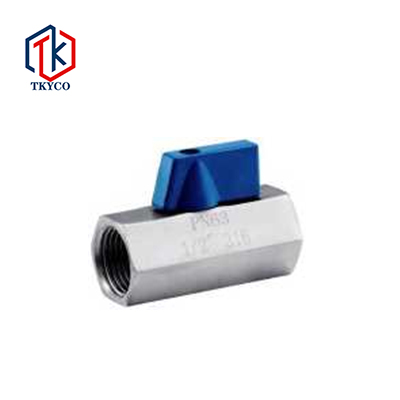

Mini Ball Valve

Technical Specification

• Design Standard: ASME B16.34

• End Connections: ASME B1.20.1(NPT) DIN2999 & BS21, ISO228/1&ISO7/1

-Test and Inspection: API 598 -

Metal Seat Ball Valve

• The series valves use forge steel or cast steel as their body material. The structure can be floating type or trunnion type ball supports.

• High precision machining results in superior ball and seat interfacing for tight shut off confomning to leakage standard of ANSI B16.104 dass VI.

• Flow direction for floating mounted type is uni-directional. Trunnion mounted type is fuly bi-directional with double-block-and-bleed capability. -

High Platform Sanitary Clamped, Welded Ball Valve

Specifications

• Nominal pressure: PN1.6,2.5,4.0,6.4Mpa

-Strength testing pressure: PT2.4,3.8,6.0, 9.6MPa

• Seat testing pressure(low pressure): 0.6MPa

• Applicable temperature: -29℃-150℃

• Applicable media:

Q41F-(16-64)C Water.Oil.Gas

Q61F-(16-64)P Nitric acid

Q81F-(16-64)R Acetic acid -

High Performance V Ball Valve

The valve plug of the high performance V ball valve is a V ball, which is a kind of rotary control valve that controls fluid flow through changing the V cut area. It is especially suitable for controlling media containing fibers or granules, such as control in applications such as paper pulp production, sewage treatment, oil product pressure stabilizing oil transportation pipeline, etc. The plug is provided with the rotary shaft at the upper and lower ends. The seat is provided with the booster ring for controlling the sealing force. When the valve is opened or closed, the V cut produces wedge shearing force with the seat, so that the sealing performance is superior to that of O ball valve, gate valve, etc. It is mainly applied in such industries as petrochemical industry, paper & pulp, light industry, water treatment, etc.

-

Gu High Vacuum Ball Valve

Appucable Range

• Smple flange(GB6070, JB919): 0.6X106-1.3X10-4Pa

• Quick release flange(GB4982): 0.1X106-1.3X10-4Pa

• Threaded connection: 1.6X106-1.3X10-4Pa

• Valve Leakage rate: w1.3X10-4Pa.L/S

• Applicable temperature: -29℃〜150℃

• Applicable medium: water, steam, oil, corrosive media. -

Gas Ball Valve

Design standards

-Design Standard: GB/T 12237, ASME.B16.34

• Flanged Ends: GB/T 91134HG/ASMEB16.5/JIS B2220

• Thread ends: ISO7/1, ISO228/1, ANSI B1.20.1

• Butt weld ends: GB/T 12224.ASME B16.25

• Face to Face: GB/T 12221 .ASME B16.10

-Test and Inspection: GB/T 13927 GB/T 26480 API598Performance Specification

•Nominal pressure: PN1.6, 2.5,4.0, 6.4Mpa

•Strength testing pressure: PT2.4, 3.8, 6.0, 9.6MPa

•Seat testing pressure(low pressure): 0.6MPa

•Applicable media: Natural gas, liquefied gas, gas, etc.

•Applicable temperature: -29°C ~150°C -

Fully-Welded Ball Valve

Design standards

• Design standards: GB/T12237/ API6D/API608

• Structure length: GB/T12221, API6D, ASME B16.10

• Connection flange: JB79, GB/T 9113.1, ASME B16.5, B16.47

• Welding end: GBfT 12224, ASME B16.25

• Test and inspection: GB/T 13927, API6D, API 598Performance Specification

-Nominal pressure: PN16, PN25, PN40,150, 300LB

• Strength test: PT2.4, 3.8, 6.0, 3.0, 7.5MPa

• Seal test: 1.8, 2.8,4.4,2.2, 5.5MPa

• Gas seal test: 0.6MPa

• The valve main material: A105(C), F304(P), F316(R)

• Suitable medium: the lonq-distance pipeline for, natural gas, petroleum, heating and thermal power pipe net.

• Suitable temperature: -29°C-150°C -

Forged Steel Ball Valve/ Needle Valve

Technical Specihcation

• Design Standard: ASME B16.34

• End Connections: ASME B12.01(NPT), DIN2999&BS21, ISO228/1&ISO7/1, SME B16.11, ASME B16.25

-Test and Inspection: API 598