Cryogenic Ball Valve Manufacturer in China: Quality Solutions for All Needs

When it comes to sourcing high-quality cryogenic ball valves, I understand how crucial it is to partner with a reliable manufacturer in China. Our cryogenic ball valves are designed to handle extreme temperatures and pressures, ensuring optimal performance in the most demanding applications. I’ve seen firsthand how our products can enhance system efficiency and reliability. Each valve undergoes rigorous testing and quality assurance processes, so I can assure you of their durability and precision. Our commitment to excellence means that not only do you receive top-notch products, but also dedicated support throughout your purchasing journey. With competitive pricing and the capacity to meet large volume orders, I’m confident that our cryogenic ball valves will meet your needs. If you’re ready to elevate your operations, consider working with us for your next project!

Cryogenic Ball Valve Dominates From Concept to Delivery

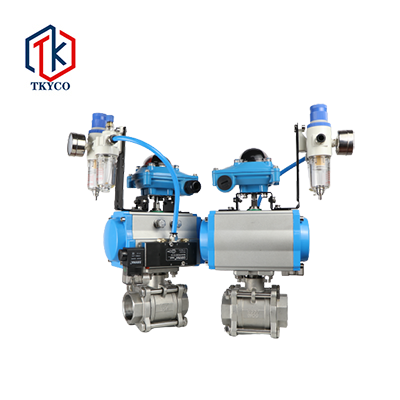

In today's increasingly competitive industrial landscape, the importance of reliable cryogenic ball valves cannot be overstated. These specialized valves are pivotal in the safe and efficient transport of liquefied gases at extremely low temperatures. From concept to delivery, the manufacturing process of cryogenic ball valves encompasses advanced engineering, precision design, and stringent quality control measures, ensuring that each product meets the highest performance standards. The innovation involved in these valves begins with cutting-edge technology and materials engineered to withstand the extreme conditions of cryogenic applications. Throughout the production process, rigorous testing ensures that each valve operates seamlessly, preventing leaks and maintaining the integrity of the system. Collaborating with experts in the field allows manufacturers to continuously refine their designs, integrating feedback from real-world applications to enhance functionality and durability. This commitment to excellence not only guarantees top-tier products but also builds trust with global procurement partners who prioritize safety and efficiency in their operations. As industries worldwide seek to optimize their supply chains and increase efficiency, sourcing high-quality cryogenic ball valves has never been more crucial. By choosing a supplier that emphasizes innovation and reliability throughout the entire manufacturing journey, procurement professionals can ensure they are equipped with the best solutions for their operational needs. Ultimately, a strategic partnership focused on quality and performance will lead to enhanced productivity and reduced downtime, solidifying a competitive advantage in the global market.

Cryogenic Ball Valve Dominates From Concept to Delivery

| Dimension | Material | Temperature Range (°F) | Pressure Rating (psi) | Actuation Type |

|---|---|---|---|---|

| 2 inch | Stainless Steel | -320 to 100 | 1500 | Electric |

| 3 inch | Carbon Steel | -320 to 200 | 2000 | Pneumatic |

| 4 inch | Alloy Steel | -320 to 150 | 2500 | Manual |

| 1.5 inch | Copper Nickel | -250 to 75 | 1200 | Hydraulic |

Related Products