Double Flange Butterfly Valve Manufacturer in China for Quality Solutions

When it comes to reliable flow control solutions, the Double Flange Butterfly Valve stands out in our offering. Designed for durability and efficiency, this valve ensures smooth operation in various industrial applications. As a seasoned manufacturer in China, we specialize in creating high-quality valves tailored to meet your specific needs. I’ve seen how our Double Flange Butterfly Valve can enhance system performance while minimizing maintenance costs. Its robust design and easy installation are perfect for both new installations and upgrades. Whether you’re managing water treatment, HVAC systems, or chemical processing, this valve provides the precision and durability you require. Our commitment to quality means you're investing in a long-lasting solution backed by expert knowledge and support. Trust in our experience as a manufacturer and let us help you optimize your operations with our exceptional products. Reach out today to learn more about how our Double Flange Butterfly Valve can make a difference in your projects.

Double Flange Butterfly Valve Application Now Trending

Double flange butterfly valves are gaining popularity in various industrial applications due to their exceptional performance, cost-effectiveness, and ease of installation. These valves, designed with a double flanged connection, provide a reliable solution for regulating flow within pipelines across diverse sectors such as water treatment, power generation, oil and gas, and chemical processing. Their robust construction ensures durability, while the lightweight design facilitates easy handling and installation, making them an ideal choice for global procurement. The trend towards double flange butterfly valves can be attributed to their versatility. They perform exceptionally well in high-pressure and high-temperature environments, making them suitable for demanding industrial conditions. Additionally, the design minimizes flow resistance, resulting in energy savings and improved efficiency in fluid transport systems. As industries adapt to stricter environmental regulations and seek sustainable solutions, the adoption of these innovative valves is likely to grow, driven by their ability to enhance operational reliability and minimize leakage risks. For procurement professionals aiming to optimize their supply chain, sourcing double flange butterfly valves can lead to improved operational efficiency and reduced maintenance costs. As the market continues to evolve, leveraging the advantages of these valves will not only enhance process control but also contribute to long-term cost savings and sustainability goals. Collaboration with reliable manufacturers who prioritize quality and innovation will be key to staying ahead in this competitive landscape.

Double Flange Butterfly Valve Application Now Trending

| Application Field | Fluid Type | Temperature Range (°C) | Pressure Range (bar) | Material Used |

|---|---|---|---|---|

| Water Treatment | Water | 0 to 70 | 1 to 10 | Cast Iron |

| Chemical Processing | Acids and Bases | -5 to 100 | 1 to 16 | PVC |

| HVAC Systems | Air | -20 to 60 | 1 to 5 | Aluminum |

| Oil and Gas | Oil | -10 to 85 | 1 to 20 | Stainless Steel |

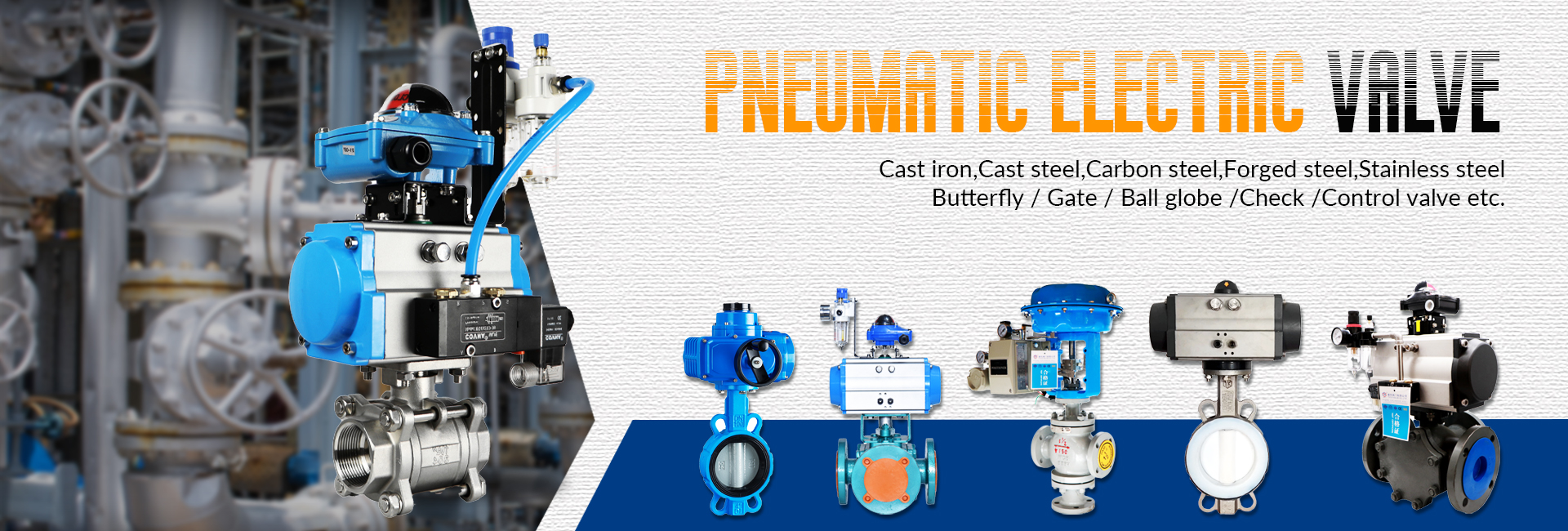

Related Products