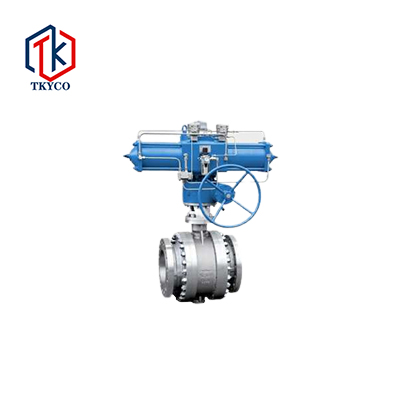

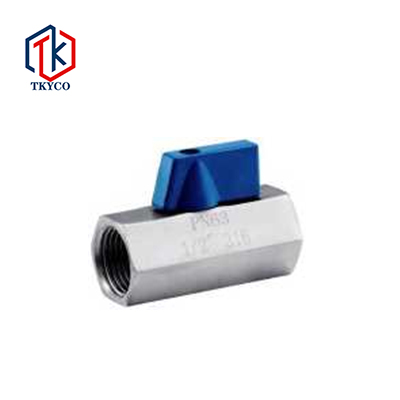

China Manufacturer of High-Quality Industrial Ball Valves

As a leading industrial ball valve manufacturer in China, we focus on delivering durability and reliability with every valve we produce. Our valves are designed to handle various pressures and temperatures, making them ideal for multiple applications in industries like oil and gas, water treatment, and chemical processing. I take pride in the rigorous testing and quality control procedures we employ, ensuring that each valve meets international standards. Our ball valves feature precision-engineered components that provide tight sealing and smooth operation, which translates to minimized downtime and reduced maintenance costs for your operations. Whether you're sourcing for a large-scale project or looking for reliable components for your assembly line, our industrial ball valves stand out for their performance and value. With tailored solutions to match your specific needs, partnering with us means you're choosing quality backed by years of expertise in the field. Let’s work together to enhance your operations!

Industrial Ball Valve Where Innovation Meets 2025 Service Backed by Expertise

In today’s rapidly evolving industrial landscape, efficiency and reliability are paramount. One crucial component in achieving operational excellence is the industrial ball valve, a staple in many sectors due to its exceptional flow control capabilities. As we look towards 2025, the integration of innovative technologies and premium service is becoming increasingly important for businesses aiming to enhance their systems and processes. With a focus on meeting the demands of global procurement, the modern industrial ball valve is designed not only for traditional applications but also for the future needs of diverse industries. The advancements in ball valve technology have led to improved performance characteristics, such as increased durability, reduced maintenance needs, and enhanced flow efficiency. These innovations are driven by expert knowledge and a commitment to quality, ensuring that these valves can withstand the rigors of demanding environments. By leveraging cutting-edge manufacturing techniques and materials, businesses can enjoy the benefits of longer service life and optimized operation, which ultimately contribute to reduced downtime and costs. In addition to superior products, the accompanying service and expertise play a critical role in the procurement process. Global buyers are looking for partners who not only provide high-quality valves but also offer comprehensive support throughout the product lifecycle. This includes everything from responsive customer service to tailored solutions that address specific operational challenges. As we step into 2025, the focus on innovation and exceptional service in the industrial ball valve market will continue to evolve, positioning companies to meet the challenges of tomorrow with confidence and precision.

Industrial Ball Valve Where Innovation Meets 2025 Service Backed by Expertise

| Feature | Details |

|---|---|

| Material | Stainless Steel 316 |

| Pressure Rating | 150 PSI |

| Temperature Range | -20°F to 300°F |

| Connection Type | Flanged |

| Actuation Type | Manual or Electric |

| Application | Oil and Gas, Water Treatment |

| Certification | ISO 9001, API 6D |

Related Products