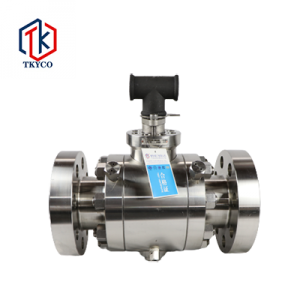

METAL SEAT (FORGED) BALL VALVE

METAL SEAT (FORGED) BALL VALVE Detail:

Product Overview

Forged steel flange type high pressure ball valve closing parts of the ball around the center line of the valve body for rotation to open and close a valve, the seal is embedded in the stainless steel valve seat, the metal valve seat is provided with a spring, when the sealing surface wear or burn, under the action of the spring to push the valve seat and the ball to form a metal seal.Exhibit unique automatic pressure release function, when the valve lumen medium pressure more than spring pre-tightening force, outlet valve seat back out of the sphere, achieve automatic relief effect, after pressure relief valve seat automatic reset, and is applicable to water, solvent, acid and gas, such as general work medium, but also is suitable for the working conditions of media, such as oxygen, hydrogen peroxide, methane and ethylene,It has been applied well in various industries.

Product structure features:

1. All parts of this product are forgings.

2, the use of bottom-mounted valve stem, set up inverted sealing structure, to ensure that the packing place reliable sealing and prevent the stem out.

3. Adopt inlaid valve seat.O-ring is set behind the valve seat to ensure that the medium does not leak out.

Product Structure

MAIN OUTER SIZE

(GB): PN40

|

DN |

L |

D |

D1 |

D2 |

b |

f |

n-Φd |

|

100 |

305 |

235 |

190 |

162 |

24 |

2 |

8-18 |

|

125 |

381 |

270 |

220 |

188 |

26 |

2 |

8-26 |

|

150 |

403 |

300 |

250 |

210 |

28 |

2 |

8-26 |

|

200 |

502 |

375 |

320 |

285 |

34 |

2 |

12-30 |

|

250 |

568 |

450 |

385 |

345 |

38 |

2 |

12-33 |

|

300 |

648 |

515 |

450 |

410 |

42 |

2 |

16-33 |

|

350 |

762 |

580 |

510 |

465 |

46 |

2 |

16-36 |

|

400 |

838 |

660 |

585 |

535 |

50 |

2 |

16-39 |

(GB): PN63

|

DN |

L |

D |

D1 |

D2 |

b |

f |

n-Φd |

|

100 |

406 |

250 |

200 |

162 |

30 |

2 |

8-26 |

|

125 |

432 |

295 |

240 |

188 |

34 |

2 |

8-30 |

|

150 |

495 |

345 |

280 |

218 |

36 |

2 |

8-33 |

|

200 |

597 |

415 |

345 |

285 |

42 |

2 |

12-36 |

|

250 |

673 |

47 |

400 |

345 |

46 |

2 |

12-36 |

|

300 |

762 |

530 |

460 |

410 |

52 |

2 |

16-36 |

|

350 |

826 |

600 |

525 |

465 |

56 |

2 |

16-39 |

|

400 |

902 |

670 |

585 |

535 |

60 |

2 |

16-42 |

(GB): PN100

|

DN |

L |

D |

D1 |

D2 |

b |

f |

n-Φd |

|

100 |

432 |

265 |

210 |

162 |

40 |

2 |

8-30 |

|

125 |

508 |

315 |

250 |

188 |

40 |

2 |

8-33 |

|

150 |

559 |

355 |

290 |

218 |

44 |

2 |

12-33 |

|

200 |

660 |

430 |

360 |

285 |

52 |

2 |

12-36 |

|

250 |

787 |

505 |

430 |

345 |

60 |

2 |

12-39 |

|

300 |

838 |

585 |

500 |

410 |

68 |

2 |

16-42 |

|

350 |

889 |

655 |

560 |

465 |

74 |

2 |

16-48 |

|

400 |

991 |

715 |

620 |

535 |

78 |

2 |

16-48 |

(ANSI): 300LB

|

DN |

L |

D |

D1 |

D2 |

b |

f |

n-Φd |

|

100 |

305 |

255 |

200 |

157.2 |

32.2 |

2 |

8-22 |

|

125 |

381 |

280 |

235 |

185.7 |

35.4 |

2 |

8-22 |

|

150 |

403 |

320 |

269.9 |

215.9 |

37 |

2 |

12-22 |

|

200 |

502 |

380 |

330.2 |

269.9 |

41.7 |

2 |

12-26 |

|

250 |

568 |

445 |

387.4 |

323.8 |

48.1 |

2 |

16-30 |

|

300 |

648 |

520 |

450.8 |

381 |

51.3 |

2 |

16-33 |

|

350 |

762 |

585 |

514.4 |

412.8 |

54.4 |

2 |

20-33 |

|

400 |

838 |

650 |

571.5 |

469.9 |

57.6 |

2 |

20-36 |

(ANSI): 600LB

| Nominal diameter |

L |

D |

D1 |

D2 |

b |

f |

n-Φd |

|

|

4″ |

100 |

432 |

275 |

215.9 |

157.2 |

45.1 |

7 |

8-25 |

|

5″ |

125 |

508 |

330 |

266.7 |

185.7 |

51.5 |

7 |

8-30 |

|

6″ |

150 |

559 |

355 |

292.1 |

215.9 |

54.7 |

7 |

12-29 |

|

8″ |

200 |

660 |

420 |

349.2 |

269.9 |

62.6 |

7 |

12-32 |

|

10″ |

250 |

787 |

510 |

431.8 |

323.8 |

70.5 |

7 |

16-35 |

|

12″ |

300 |

838 |

560 |

489 |

381 |

73.7 |

7 |

20-35 |

|

14″ |

350 |

889 |

605 |

527 |

412.8 |

76.9 |

7 |

20-38 |

(ANSI): 900LB

| Nominal diameter |

L |

D |

D1 |

D2 |

b |

f |

n-Φd |

|

|

4″ |

100 |

432 |

290 |

235 |

157.2 |

51.5 |

7 |

8-32 |

|

5″ |

125 |

508 |

350 |

279.4 |

185.7 |

57.8 |

7 |

8-36 |

|

6″ |

150 |

559 |

380 |

317.5 |

215.9 |

62.6 |

7 |

12-32 |

|

8″ |

200 |

660 |

470 |

393.7 |

269.9 |

70.5 |

7 |

12-38 |

|

10″ |

250 |

787 |

545 |

469.9 |

323.8 |

76.9 |

7 |

16-38 |

|

12″ |

300 |

838 |

610 |

533.4 |

381 |

86.4 |

7 |

20-38 |

|

14″ |

350 |

889 |

640 |

558.8 |

412.8 |

92.8 |

7 |

20-42 |

|

16″ |

400 |

991 |

705 |

616 |

469.9 |

95.9 |

7 |

20-45 |

Product detail pictures:

Related Product Guide:

we can offer high quality products, competitive price and best customer service. Our destination is You come here with difficulty and we give you a smile to take away for METAL SEAT (FORGED) BALL VALVE , The product will supply to all over the world, such as: Juventus , Islamabad , Malta , Since its foundation , the company keeps living up to the belief of honest selling , best quality , people-orientation and benefits to customers. We are doing everything to offer our customers with best services and best products . We promise that we'll be responsible all the way to the end once our services begin.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.