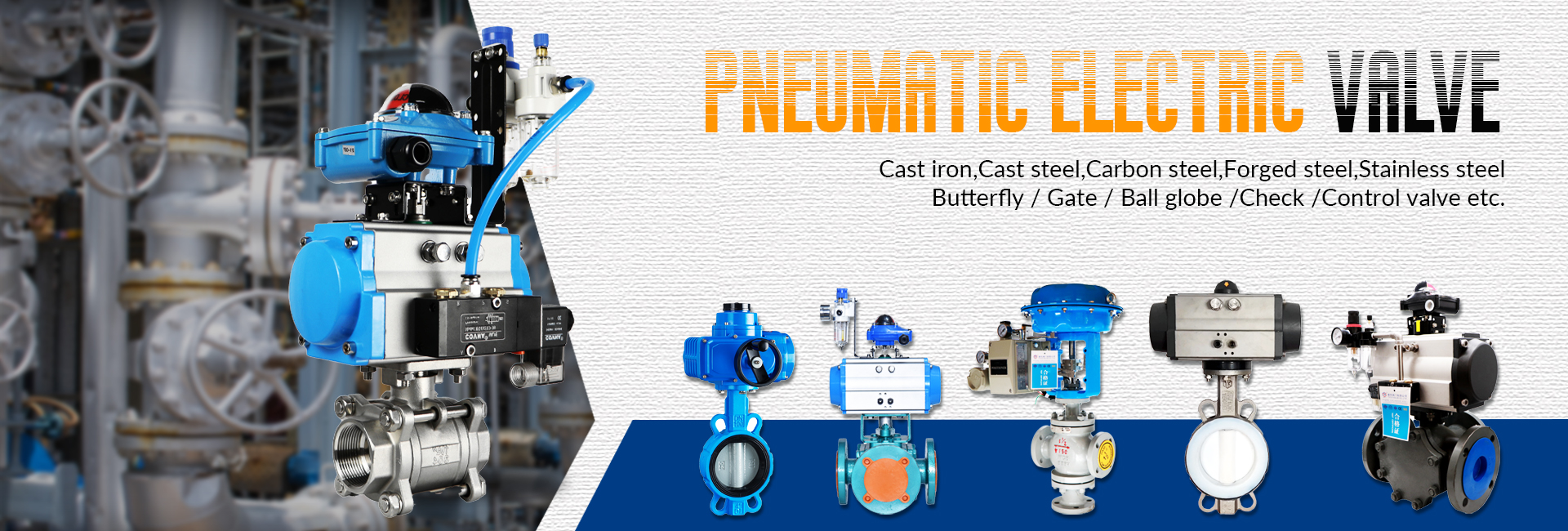

Top China Manufacturer of Spring Loaded Ball Valves for Optimal Performance

When it comes to reliable fluid control solutions, I've found that the Spring Loaded Ball Valve stands out in performance and durability. Designed for various industrial applications, these valves ensure efficient operation with minimal leak risks. I appreciate that they are designed to maintain pressure and work smoothly even in demanding environments. Sourcing from a reputable manufacturer in China, I can trust that the materials and craftsmanship meet high quality standards. This makes a difference in the long run, not only to reduce maintenance costs but also to enhance system reliability. Plus, having access to a manufacturer means I can benefit from competitive prices and customized solutions tailored to my specific needs. If you're serious about enhancing your operations with top-grade spring loaded ball valves, I highly recommend considering options that combine quality and value from established suppliers.

Spring Loaded Ball Valve Winning in 2025 Where Innovation Meets 2025

As we approach 2025, the spotlight shines brightly on spring-loaded ball valves—an innovative solution revolutionizing various industries. These valves, known for their efficient performance and reliability, are becoming increasingly essential in energy, water management, and manufacturing sectors. The unique design utilizes a spring mechanism that ensures optimal sealing and minimal leakage, making them ideal for high-pressure and dynamic applications. What sets spring-loaded ball valves apart is their ability to adapt to fluctuating operational demands. As global industries pivot towards automation and sustainability, these valves can facilitate enhanced control over fluid flow and reduce energy consumption. The integration of advanced materials and smart technology positions them as a preferred choice for procurement professionals seeking cost-effective, durable, and eco-friendly solutions. As we look toward the future, it is clear that innovation will play a pivotal role in the evolution of ball valve technology. Companies around the world are urged to stay informed on the latest advancements, providing a competitive edge in procurement strategies. Embracing these cutting-edge solutions now is key to aligning with the demands of tomorrow’s market, ensuring businesses thrive in an increasingly complex global landscape.

Spring Loaded Ball Valve Winning in 2025 Where Innovation Meets 2025

| Feature | Description | Application | Advantages | Innovations |

|---|---|---|---|---|

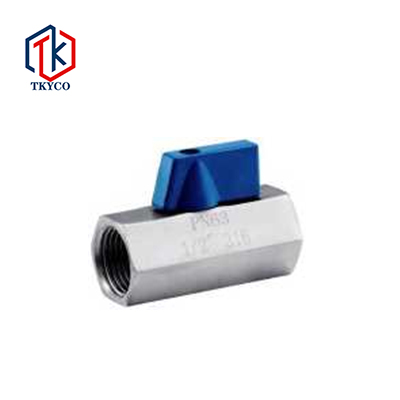

| Material Composition | High-strength alloys and polymers | Oil and gas, water treatment | Corrosion resistance and high durability | Enhanced fatigue resistance technology |

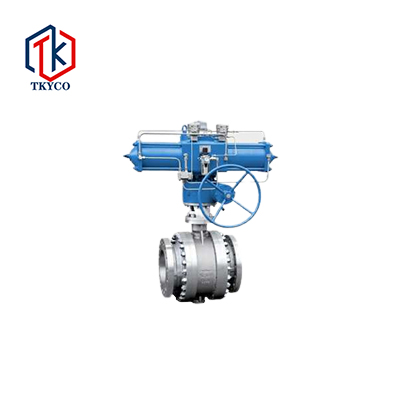

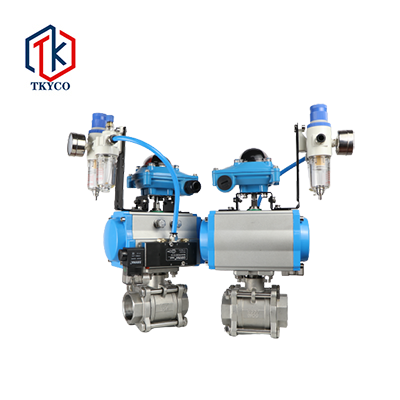

| Sealing Mechanism | Self-adjusting seal | Chemical processing | Leak-proof operation | Smart sealing technology |

| Actuation Type | Spring-loaded | HVAC systems | Quick response time | Automated control integration |

| Size Range | 1/4" to 12" | Industrial piping | Versatility for various applications | Modular design for easy upgrades |

| Maintenance | Low maintenance requirements | Food and beverage processing | Reduced downtime | Self-diagnostic features |

Related Products