Top Steam Stop Valve Manufacturer in China for Quality Solutions

As a reliable supplier of steam stop valves, I understand the importance of quality and durability in industrial applications. Our steam stop valves are designed and manufactured right in China, ensuring that you get the best possible performance. I pride myself on delivering products that meet strict industry standards, offering you peace of mind knowing you’re investing in a reliable solution. Our valves feature robust construction and precise engineering, making them ideal for various applications. Whether you require them for power plants or manufacturing processes, you won’t be disappointed in their effectiveness. Plus, with our competitive pricing and commitment to customer service, I’m here to ensure your buying experience is seamless. If you’re seeking a trusted manufacturer with years of experience in the industry, you’ve come to the right place. Let’s connect and discuss how our steam stop valves can meet your business needs.

Steam Stop Valve Application Ahead of the Curve

In the rapidly evolving industrial landscape, the demand for high-performance steam stop valves has never been more pronounced. These essential components play a crucial role in regulating the flow of steam across various applications, ensuring efficiency and safety in operations. As industries strive to optimize their processes, investing in advanced steam stop valves can lead to significant operational improvements. Utilizing cutting-edge technology in valve design, modern steam stop valves offer exceptional reliability and durability, catering to the stringent requirements of global industries such as power generation, chemical processing, and manufacturing. Their precise control mechanisms not only enhance system performance but also contribute to energy conservation and reduced operational costs. As procurement specialists seek out innovative solutions, it is paramount to consider suppliers who prioritize quality and technological advancement. Moreover, with an increasing focus on sustainability and regulatory compliance, the role of steam stop valves is evolving. Partners who provide comprehensive support, including guidance on installation, maintenance, and regulatory adherence, will be invaluable in navigating this complex landscape. By embracing these advanced solutions early, businesses can stay ahead of the competition, ensuring a successful transition to more efficient and sustainable operations.

Steam Stop Valve Application Ahead of the Curve

| Application Area | Valve Type | Material | Temperature Range (°C) | Pressure Rating (bar) |

|---|---|---|---|---|

| Power Plants | Globe Valve | Carbon Steel | -10 to 200 | 40 |

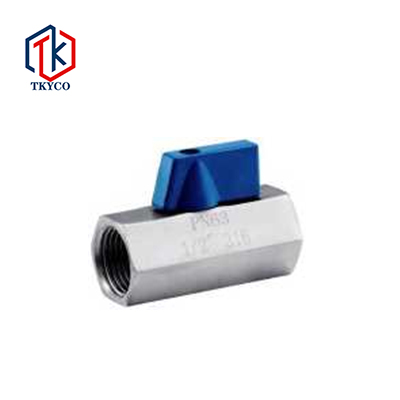

| Chemical Processing | Ball Valve | Stainless Steel | -20 to 150 | 30 |

| Oil and Gas | Gate Valve | Alloy Steel | -40 to 250 | 50 |

| Food Industry | Butterfly Valve | PVC | 0 to 90 | 10 |

Related Products