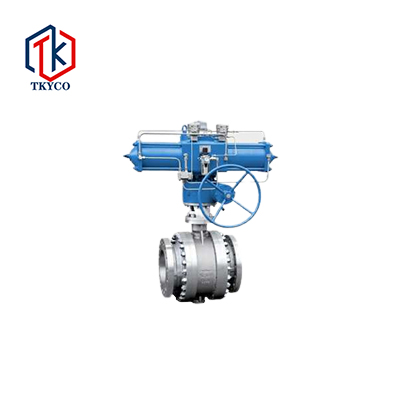

Top China Manufacturer of Durable Welded Ball Valves for Your Needs

As a trusted supplier of high-quality welded ball valves in China, I understand the importance of reliability and efficiency in your operations. Our welded ball valves are constructed to withstand high pressure and temperature, making them an ideal choice for various industrial applications. Designed with precision engineering, they provide excellent flow control and minimal leakage, ensuring optimal performance in your systems. I take pride in our manufacturing process, which adheres to stringent quality standards to deliver durable and long-lasting products. Whether you're in oil and gas, water treatment, or manufacturing, our welded ball valves meet your specific requirements. Partnering with us means you get not just a product, but a reliable solution that enhances your operations. Trust in our commitment to quality and service to help drive your projects to success. Let's elevate your workflow with our exceptional welded ball valves – because your needs deserve nothing less.

Welded Ball Valve Application Now Trending

Welded ball valves have emerged as a trending choice in various industries, owing to their remarkable durability and reliability in high-pressure applications. These valves are designed to handle extreme conditions, making them ideal for sectors such as oil and gas, chemical processing, and water treatment. Their unique welded construction provides a secure seal and significantly reduces the risk of leakage, enhancing overall system safety and efficiency. As the demand for robust and long-lasting valve solutions increases, global procurement agents are seeking dependable suppliers who can deliver high-quality welded ball valves. One of the key advantages of welded ball valves is their ability to minimize maintenance needs. Traditional bolted valves often suffer from wear and tear over time, leading to frequent replacements and downtime. In contrast, welded ball valves boast a more resilient design, enabling continuous operation in challenging environments. This not only lowers operational costs for businesses but also extends the lifespan of the entire piping system. As industries become more conscious of sustainability and cost-effectiveness, the growing preference for welded ball valves reflects a significant trend in procurement strategies. Moreover, the versatility of welded ball valves allows them to be tailored for specific applications with various materials and coatings. This adaptability ensures compatibility with diverse media, including corrosive substances and high-temperature steam. As global energy demands continue to rise, the shift towards reliable and efficient valve solutions highlights the importance of staying informed about the latest trends in the market. For procurement professionals, investing in welded ball valves can enhance both the performance and reliability of their operations, aligning with the evolving needs of modern industrial processes.

Welded Ball Valve Application Now Trending

| Application Area | Material Type | Size Range | Temperature Rating |

|---|---|---|---|

| Oil & Gas Industry | Stainless Steel | 1" - 12" | -20°C to 150°C |

| Water Treatment | Carbon Steel | 1/2" - 10" | 0°C to 100°C |

| Chemical Processing | Alloy Steel | 3/4" - 8" | -10°C to 180°C |

| Food and Beverage | Hygienic Stainless Steel | 1" - 6" | -5°C to 120°C |

| HVAC Systems | Bronze | 1/2" - 4" | -10°C to 80°C |

Related Products