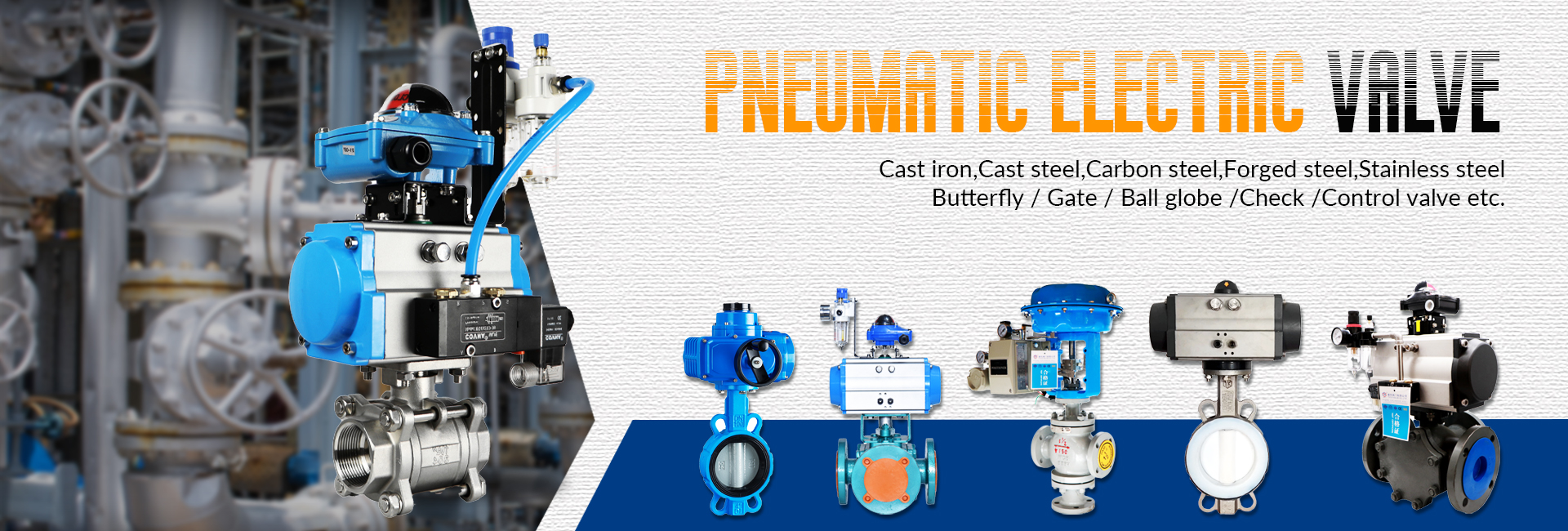

Top China Manufacturer of Butterfly Valve Actuators for Optimal Control

Our Butterfly Valve Actuator is the ideal solution for enhancing the efficiency of your industrial applications. I come from a reputable manufacturer based in China, specializing in high-quality valve automation products. With years of experience, we understand the specific demands of various industries, ensuring our actuators offer reliability and performance. The construction is robust, allowing for seamless operation in harsh environments. I’ve seen firsthand how our actuators simplify the control of flow, giving you precise and responsive adjustments when you need them most. Whether you are dealing with water treatment, HVAC systems, or any other application, our Butterfly Valve Actuator is designed to meet your operational requirements. Choose us as your trusted partner to not only receive a superior product but also gain valuable support throughout your purchasing journey. With us, you can count on quality and service that stands out. Let’s make your processes smoother and more effective together!

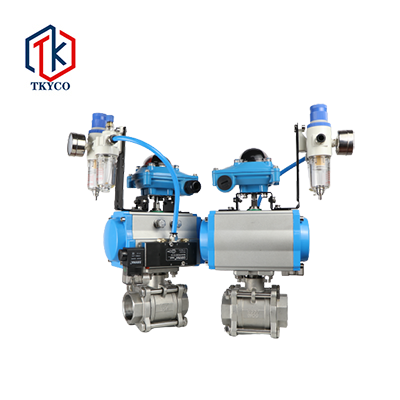

Butterfly Valve Actuator Is The Best Factory-Direct Excellence

When it comes to optimizing industrial processes, choosing the right valve actuator is crucial. Butterfly valve actuators offer a combination of efficiency, reliability, and versatility, making them an ideal solution for various applications across industries. Factory-direct purchasing ensures that you receive high-quality products directly from the manufacturer, minimizing middlemen costs while ensuring that you get the best value for your investment. These actuators are designed with cutting-edge technology, providing superior performance and longevity compared to conventional models. The benefits of selecting a factory-direct butterfly valve actuator extend beyond just cost savings. Comprehensive quality control measures are implemented during manufacturing, ensuring that each actuator meets stringent industry standards. Furthermore, factory-direct options often come with customizable features tailored to specific operational requirements, enhancing performance in unique environments. By collaborating directly with manufacturers, procurement professionals can also access extensive support and expertise, ensuring that they make informed decisions that align with their operational goals. In an increasingly competitive global market, opting for factory-direct solutions is a strategic choice that enables companies to maintain productivity while managing costs effectively. With an emphasis on excellence in design and manufacturing, butterfly valve actuators represent a robust solution that yields both operational efficiency and reliability. Investing in these high-quality actuators positions businesses to enhance their capabilities and achieve sustainable growth in their respective sectors.

Butterfly Valve Actuator Is The Best Factory-Direct Excellence

| Feature | Description | Material | Size Range | Application |

|---|---|---|---|---|

| Actuation Type | Electric or Pneumatic | Aluminum, Stainless Steel | 2" to 48" | Water, Oil, Gas |

| Control Options | On/Off, Modulating | Cast Iron, PVC | 1" to 24" | HVAC, Chemical Processing |

| Sealing Method | Soft Seat, Metal Seat | Rubber, Teflon | 3" to 36" | Pharmaceuticals, Water Treatment |

| Operating Temperature | -20°C to 150°C | Bronze, PVC | 2" to 10" | Marine, Food Processing |

Related Products