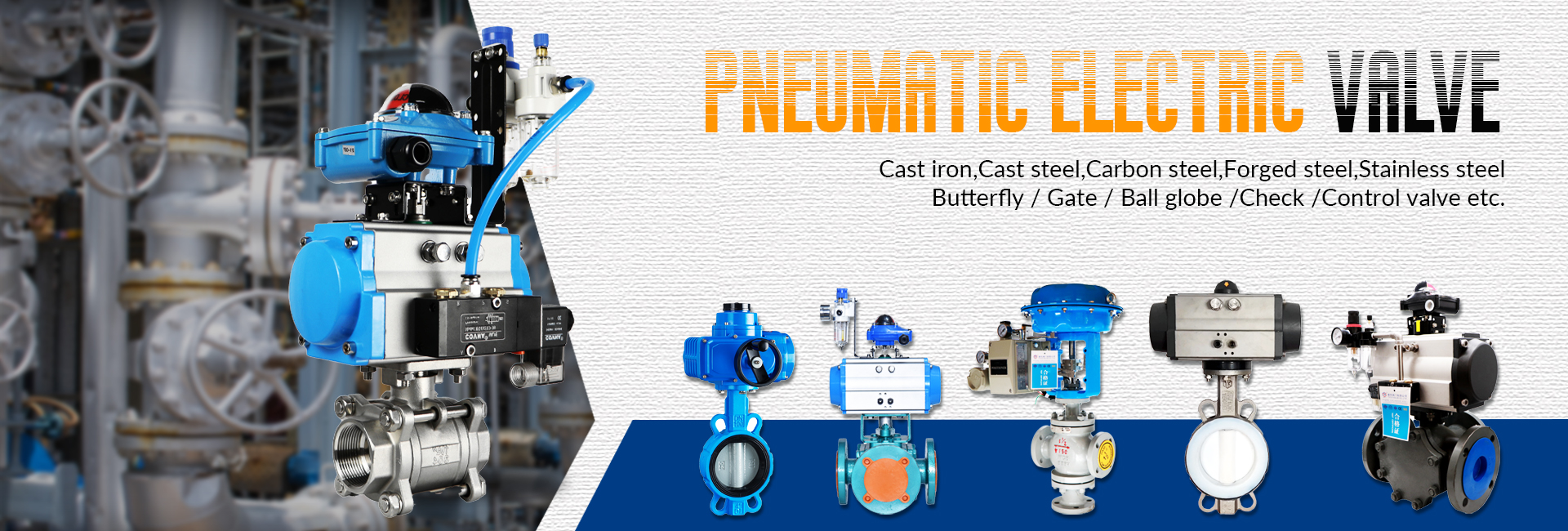

Top China Manufacturer of CI Gate Valves for Quality Performance

As a professional in the valve industry, I understand the importance of quality and reliability, especially when it comes to the CI Gate Valve. Sourced from leading manufacturers in China, our CI Gate Valves are designed to meet the rigorous demands of various industrial applications. With robust construction and precise engineering, these valves offer exceptional performance and durability, ensuring smooth operation in your systems. We pride ourselves on our commitment to excellence and have partnered with experienced manufacturers who share our vision for high standards. Whether you're looking to enhance your production efficiency or ensure safety in your processes, our CI Gate Valves provide the reliable solution you need. Choosing our products not only gives you access to top-tier technology but also supports your operational goals. Let’s collaborate to find the right CI Gate Valve for your requirements and elevate your projects to new heights.

Ci Gate Valve Application Service Backed by Expertise

When it comes to reliable industrial solutions, the application of CI gate valves stands out as a critical component in various sectors. These valves are designed to provide efficient control over the flow of liquids and gases, ensuring safety and optimal operation in demanding environments. Industries such as oil and gas, water treatment, and chemical processing are increasingly adopting CI gate valves due to their robust construction and exceptional performance. With expert support, users can maximize the advantages of these valves, ensuring they meet their specific operational needs. Understanding the technical intricacies and the unique requirements of different applications is crucial to achieving efficiency and reliability. Expertise in valve selection and installation can significantly impact system performance and durability. By leveraging a wealth of experience, our service can assist global buyers in navigating the complexities of valve specifications, ensuring that they choose the right product for their specific requirements. This commitment to quality service not only enhances operational security but also translates into long-term cost savings for businesses on a global scale. Procuring high-quality CI gate valves backed by industry expertise ensures that your operations are not only compliant with global standards but are also optimized for performance. Engaging with knowledgeable partners in the field allows procurement strategies to align closely with technological advancements and market demands. As we aim to equip industries worldwide with superior valve solutions, we guarantee support that fosters innovation and efficiency in every application.

Ci Gate Valve Application Service Backed by Expertise

| Application Area | Material Type | Size Range (inches) | Temperature Rating (°F) | Pressure Rating (PSI) | Expertise Provided |

|---|---|---|---|---|---|

| Water Supply | Cast Iron | 2 - 12 | 32 - 150 | 150 | Installation & Maintenance |

| Chemical Processing | Stainless Steel | 1 - 10 | 0 - 300 | 300 | Custom Solutions |

| Oil and Gas | Forged Steel | 3 - 16 | -40 - 200 | 600 | Technical Support |

| Power Generation | Ductile Iron | 4 - 20 | 100 - 400 | 400 | Field Services |

| HVAC Systems | Bronze | ½ - 6 | 32 - 180 | 250 | Consultation |

Related Products