High-Quality Compression Shut Off Valve Manufacturer in China

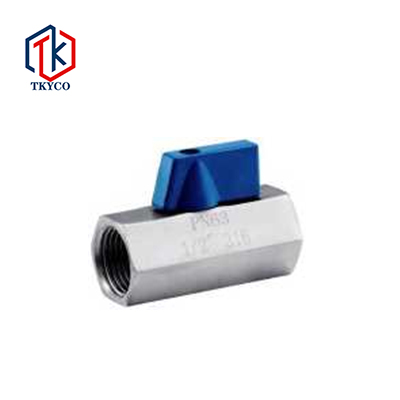

With our Compression Shut Off Valve, I’m excited to offer a reliable solution that meets your precise needs in a variety of applications. Manufactured in China, this valve ensures top-notch quality and performance, crafted specifically for rugged environments. Its durable design guarantees optimal flow control while simplifying maintenance. I understand the importance of efficiency and reliability in your operations, which is why this valve is engineered for seamless integration into your systems. Whether you’re working in industrial, commercial, or residential environments, this valve offers versatility that you can trust. By choosing us as your manufacturer, you’re not just getting a product; you’re investing in a partnership with a company that prioritizes your satisfaction. Let’s enhance your project with our expertly crafted Compression Shut Off Valve. Reach out to us today to learn more about how we can support your business goals!

Compression Shut Off Valve Industry Giant From Concept to Delivery

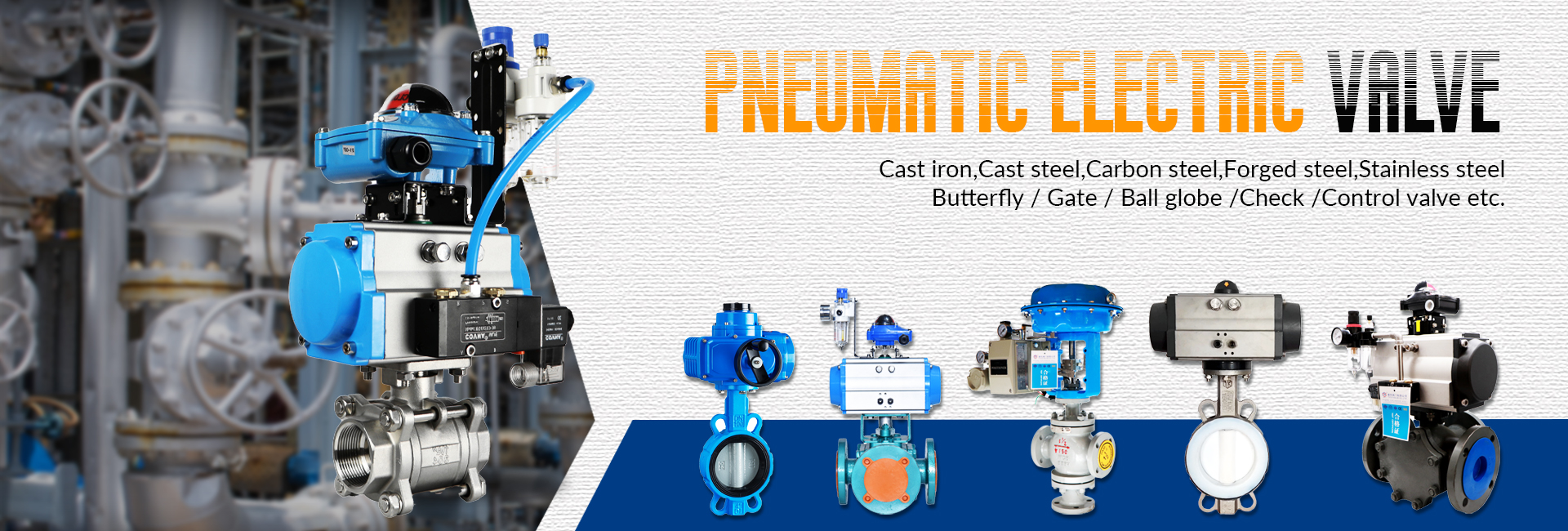

In the fast-evolving landscape of industrial valve manufacturing, the Compression Shut Off Valve has emerged as a critical component for various applications. From initial concept design to final delivery, the journey of these valves illustrates the integration of advanced engineering techniques and stringent quality standards. The industry is experiencing a surge in demand, driven by advancements in automation and the growing need for efficient fluid control solutions in sectors like oil and gas, petrochemical, and water treatment. The development process begins with meticulous research and innovative design, ensuring that each compression shut off valve meets the specific requirements of its intended application. Utilizing cutting-edge technology, manufacturers can create valves that not only enhance operational efficiency but also comply with international safety and environmental standards. Each phase, from prototyping to rigorous testing, emphasizes durability and reliability, essential attributes for any high-stakes industrial setting. Once the product has passed all quality assurance tests, it is streamlined into the delivery phase, where logistics plays a vital role. Coordinated supply chain management ensures that clients worldwide receive their orders promptly, minimizing downtime and maintaining productivity. As the demand for customizable solutions rises, manufacturers are also focusing on providing tailored options, enabling procurement professionals to find the perfect fit for their unique operational needs. With a commitment to excellence, the industry remains poised for continued growth, driven by innovation and customer-centric solutions.

Compression Shut Off Valve Industry Giant From Concept to Delivery

| Phase | Description | Key Steps | Expected Outcome |

|---|---|---|---|

| Concept | Initial idea generation and market research. | Identify market needs, Brainstorm features, Competitor analysis | Viable concept ready for development. |

| Design | Creating detailed designs and specifications. | Drafting technical drawings, Software modeling, Prototype development | Comprehensive design documentation. |

| Testing | Rigorous testing of prototypes for performance and safety. | Functional testing, Safety assessments, Compliance checks | Validated product ready for production. |

| Production | Manufacturing of the final product. | Set up production line, Quality control measures, Supply chain management | Mass production of valves. |

| Delivery | Shipping products to customers or stores. | Logistics planning, Distribution network setup, Customer notifications | Ensured product availability in the market. |

Related Products