Cryogenic Globe Valve Manufacturer in China - Quality and Reliability

When searching for high-quality cryogenic globe valves, you've come to the right place. As a manufacturer based in China, we specialize in producing cryogenic globe valves that meet the strictest industry standards. Our valves are designed to perform reliably in extreme temperatures, ensuring optimal flow control and safety for your operations. I understand the importance of durability and efficiency in your projects, and our valves are built from the finest materials to withstand challenging conditions. Whether you’re in the petrochemical, natural gas, or LNG industries, our cryogenic globe valves provide the performance you need. Choose our products for their exceptional sealing capabilities and ease of maintenance. With competitive pricing and a commitment to quality, we strive to build lasting partnerships with our clients. Let’s work together to enhance your operations with our top-notch cryogenic solutions. Reach out to us today for more information!

Cryogenic Globe Valve Application Service

Cryogenic globe valves are essential components in various industries, particularly in the handling of liquefied gases at extremely low temperatures. These specialized valves are designed to ensure the safe and efficient control of cryogenic fluids, making them indispensable in sectors such as LNG (Liquefied Natural Gas) production, transportation, and storage. When selecting the right cryogenic globe valve, it is crucial to consider features such as insulation, materials, and pressure ratings to ensure optimal performance and reliability in demanding environments. The application service for cryogenic globe valves extends beyond mere installation; it encompasses a comprehensive approach that includes custom engineering solutions, routine maintenance, and prompt after-sales support. Understanding the specific requirements and challenges faced by clients in the cryogenic industry allows manufacturers to provide tailored services that enhance operational efficiency and safety. This proactive approach not only maximizes the lifespan of the valves but also minimizes downtime, ultimately leading to cost savings for businesses. As the demand for liquefied gases continues to rise globally, the importance of high-quality cryogenic globe valves and exceptional service becomes increasingly evident. By investing in reliable valve technology and robust application services, procurement professionals can ensure their operations are equipped to meet future challenges while adhering to the highest safety and performance standards.

Cryogenic Globe Valve Application Service

| Application Area | Material | Temperature Range (°C) | Pressure Rating (bar) | End Connection Type |

|---|---|---|---|---|

| Cryogenic Liquefied Natural Gas (LNG) | Stainless Steel | -196 to -40 | 16 | Welded |

| Industrial Gas Storage | Carbon Steel | -150 to 20 | 10 | Flanged |

| Cryogenic Food Processing | Duplex Stainless Steel | -196 to 100 | 25 | Tri-Clamp |

| Rocket Propellant Systems | Titanium | -253 to 30 | 20 | Welded |

| Cryogenic Research Facilities | Aluminum | -273 to 100 | 5 | Socket Weld |

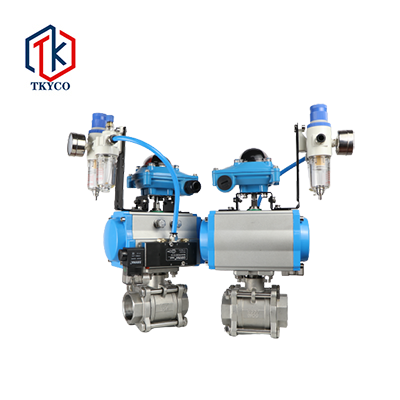

Related Products