Electric Ball Valve Manufacturer in China: Quality & Reliability Assured

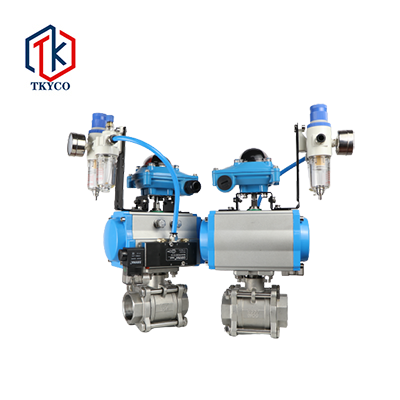

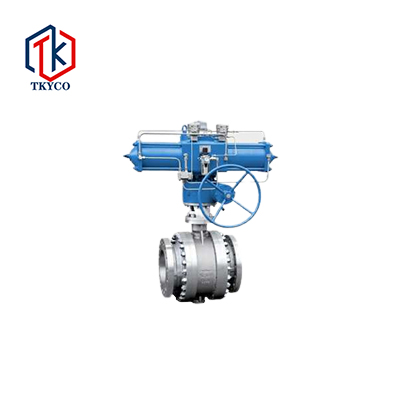

When it comes to reliable control over fluid flow, I trust the quality of Electric Ball Valves sourced from China. Manufactured with precision, these valves offer superior performance and durability, essential for various industrial applications. The electric operation ensures a hassle-free experience, allowing for quick response times and reduced manual labor. I appreciate how these valves can handle high pressure and temperature, making them versatile for different environments. As a buyer, the combination of advanced technology and cost-effectiveness makes these valves stand out. Each unit is rigorously tested, assuring high standards and reliability that every B2B purchaser seeks. Choosing an Electric Ball Valve from a reputable Chinese manufacturer is a decision that guarantees efficiency and longevity in operations. Whether you’re in manufacturing, energy, or any sector requiring fluid management, I've found that these valves consistently meet my needs and exceed expectations.

Electric Ball Valve Dominates Where Service Meets Innovation

In the fast-evolving world of industrial automation, electric ball valves have emerged as essential components where service meets innovation. These advanced valves are designed to enhance operational efficiency, providing seamless integration with modern control systems. Their ability to offer precise flow control, quick response times, and a significant reduction in maintenance down-time makes them a preferred choice for various applications, including water treatment, oil and gas, and chemical processing. The innovative design of electric ball valves minimizes the risk of leakage and ensures durability in demanding environments. With features such as smart actuators and user-friendly interfaces, they empower operators to achieve enhanced control over fluid dynamics. Additionally, the adaptability of these valves to various media types and pressure ranges positions them as versatile solutions for global buyers seeking reliability and performance. As industries worldwide strive for sustainability and cost-effectiveness, electric ball valves represent a catalyst for change. Their energy-efficient design not only reduces operational costs but also aligns with the push towards greener technologies. The increasing demand for automated solutions in process industries highlights the importance of investing in cutting-edge valve technology that meets today's challenges while paving the way for a more innovative future.

Electric Ball Valve Dominates Where Service Meets Innovation

| Feature | Description | Application Area | Innovation Aspect |

|---|---|---|---|

| High Flow Rate | Designed to handle large volumes of fluid | Industrial piping systems | Efficiency in high-demand applications |

| Durability | Construction with robust materials to withstand harsh environments | Oil and gas industry | Longevity with minimal maintenance |

| Smart Technology Integration | Compatible with IoT systems for remote monitoring and control | Smart homes and automated factories | Enhanced operational control and data collection |

| Compact Design | Space-saving design without compromising performance | Confined spaces in residential and commercial buildings | Flexibility in installation |

| Energy Efficiency | Minimizes energy consumption during operation | Water treatment plants | Cost savings in energy bills |

Related Products