Top Flow Control Valve Manufacturers in China: Quality & Reliability

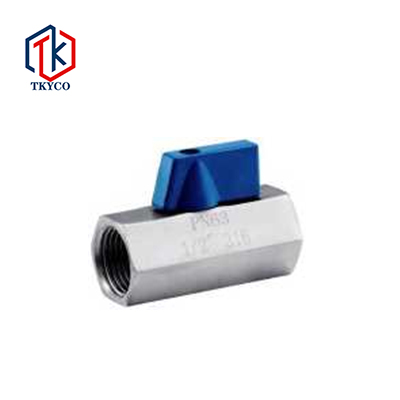

When I've been in need of reliable flow control solutions, I often turn to the expertise of manufacturers in China. The Flow Control Valve I found offers exceptional precision and durability, crucial for managing the flow of liquids and gases in various industrial applications. It’s designed to ensure optimal performance under varying pressures and temperatures, making it a versatile choice for my projects. I appreciate that these valves can handle complex systems while maintaining efficiency, which ultimately saves time and costs in the long run. Sourcing from a trusted Chinese manufacturer not only provides quality assurance but also competitive pricing and swift delivery. Whether I'm working in construction, oil & gas, or water management, having a dependable Flow Control Valve gives me the confidence to tackle any challenge.

Flow Control Valve in 2025 Your Trusted OEM Partner

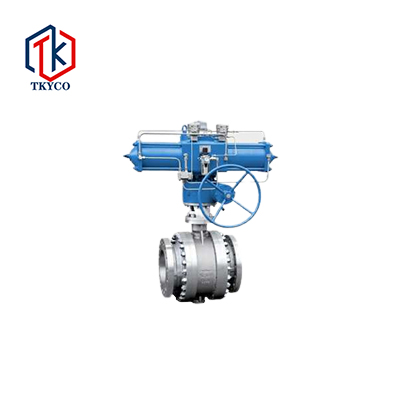

As we look ahead to 2025, the importance of reliable flow control valves in industrial applications cannot be overstated. With rapid advancements in technology and increasing demands for efficiency, procurement teams across the globe are seeking trusted OEM partners who understand their unique needs. The evolution of flow control valve technology is paving the way for smarter solutions that enhance operational performance and ensure safety across various sectors, including oil and gas, water treatment, and manufacturing. In this dynamic landscape, the role of an experienced partner becomes critical. By collaborating closely with manufacturers who prioritize innovation, quality, and customization, buyers can secure products that not only meet regulatory standards but also provide significant competitive advantages. The future of flow control valves will likely see the integration of IoT capabilities, allowing for real-time monitoring and predictive maintenance, which can dramatically reduce downtime and improve productivity. Choosing the right OEM partner today can set the foundation for a successful tomorrow. As companies navigate the complexities of supply chains and seek sustainable solutions, a trusted partner brings invaluable expertise and support. The collaboration will not only drive efficiency but also foster growth in an ever-evolving market, ensuring that you remain ahead of the curve in the competitive landscape of 2025 and beyond.

Flow Control Valve in 2025 Your Trusted OEM Partner

| Valve Type | Material | Connection Type | Size (Inches) | Pressure Rating (PSI) | Temperature Range (°F) |

|---|---|---|---|---|---|

| Ball Valve | Carbon Steel | Flanged | 2 | 150 | -20 to 300 |

| Gate Valve | Stainless Steel | Welded | 3 | 300 | 0 to 400 |

| Check Valve | Bronze | Screwed | 1.5 | 200 | -10 to 250 |

| Globe Valve | Ductile Iron | Flanged | 4 | 150 | -20 to 300 |

| Butterfly Valve | PVC | Wafer | 6 | 150 | -10 to 180 |

Related Products