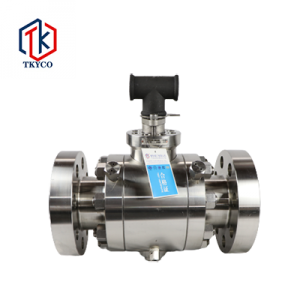

Forged Steel Globe Valve

Product Structure

main size and weight

J41H(Y) GB PN16-160

|

Size |

PN |

L(mm) |

PN |

L(mm) |

PN |

L(mm) |

PN |

L(mm) |

PN |

L(mm) |

PN |

L(mm) |

|

| in | mm | ||||||||||||

|

1/2 |

15 |

PN16 |

130 |

PN25 |

130 |

PN40 |

130 |

PN63 |

170 |

PN100 |

170 |

PN160 |

170 |

|

3/4 |

20 |

150 |

150 |

150 |

190 |

190 |

190 |

||||||

|

1 |

25 |

160 |

160 |

160 |

210 |

210 |

210 |

||||||

|

1 1/4 |

32 |

180 |

180 |

180 |

230 |

230 |

230 |

||||||

|

1 1/2 |

40 |

200 |

200 |

200 |

260 |

260 |

260 |

||||||

|

2 |

50 |

230 |

230 |

230 |

300 |

300 |

300 |

||||||

J41H(Y) ANSI 150-2500LB

|

Size |

Class |

L(mm) |

Class |

L(mm) |

Class |

L(mm) |

Class |

L(mm) |

Class |

L(mm) |

Class |

L(mm) |

|

|

in |

mm |

||||||||||||

|

1/2 |

15 |

150LB |

108 |

300LB |

152 |

600LB |

165 |

800LB |

216 |

1500LB |

216 |

2500LB |

264 |

|

3/4 |

20 |

117 |

178 |

190 |

229 |

229 |

273 |

||||||

|

1 |

25 |

127 |

203 |

216 |

254 |

254 |

308 |

||||||

|

1 1/4 |

32 |

140 |

216 |

229 |

279 |

279 |

349 |

||||||

|

1 1/2 |

40 |

165 |

229 |

241 |

305 |

305 |

384 |

||||||

|

2 |

50 |

203 |

267 |

292 |

368 |

368 |

451 |

||||||

Write your message here and send it to us