High Performance V Ball Valve

Summary

The V cut has large adjustable ratio and equal percentage flow characteristic, realizing stable control of pressure and flow.

Simple structure, small volume, light weight, smooth flow channel.

Provided wrth large nut elastic automatic compensation structure to effectively control the sealing face of seat and plug and realize good sealing performance. The eccentric plug and seat structure can reduce wear.

The V cut produces wedge shearing force wrth the seat to shut off media containing fibers. It is especially suitable for opening and controlling media of high viscosity and media containing fibers and granules.

Body

• Type: eccentric angular travel integral ball, jacket ball

• Nominal diameter (DN): 1"~20"

• Nominal pressure (PN): ANSI 150LB-900LB

• Type of connection: flange connection or wafer type

• Material: A216-WCB, A351-CF8, A351-CF8M (or forgings)

• Packing: PTFE impregnated asbestos, PTFE, flexible graphite Heat preservation jacket butterfly valve can also be offered according to user requirements.

-Trim

• Plug type: spherical ball with V cut

• Plug material: A351-CF8, CF8M carbonizing or surfeze hard cty spray voiding

• Seat material and workng temperature:

Soft seal:

PTFE -20-+180℃

filed PTFE -20-+180℃

PPL -40~+350℃

Hard seal (y): A351-CF8, CF8M

carbonizing or surface hard alloy spray welding -40+450℃

Valve shaft material: A276-420, A564-630

Sleeve material: A182-F304, A182-F316 (nitriding) or

WMS (high temperature alloy)

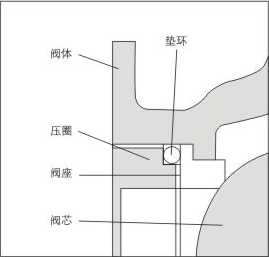

• Figure 1 Soft seal type

Plug: A351-CF8, A351-CF8M

Seat material: PTFE, filled PTFE, PPL

Seat leakage: zero leakage

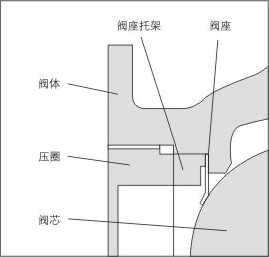

• Figure 2 Steel sheet type metal seal

Plug material: A351-CF8, CF8M nitriding or surface spray welding

Seat material: 3J1, Inconel stainless steel sheet

Seat leakage: As per ANSI B16.104 class IV-VI sealing

Rated within KVx0.00l% (250°C)

Rated within KVx0.005% (400°C)

Product Structure

igure 1 Soft seal structural diagram

Figure 2 Steel sheet type metal hard seal structural diagram

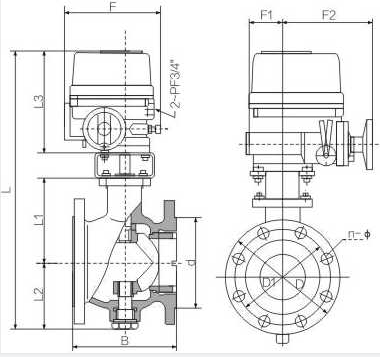

Outune And Connection Dimensions

|

DN |

L |

PN16 |

L |

150LB |

10K |

|||||||||

|

D |

D1 |

d |

n-Φ |

D |

D1 |

d |

n-Φ |

D |

D1 |

d |

n-Φ |

|||

|

25 |

450 |

115 |

85 |

65 |

4-Φ14 |

102 |

110 |

79.4 |

50.8 |

4-16 |

125 |

90 |

67 |

4-19 |

|

32 |

470 |

140 |

100 |

76 |

4-Φ18 |

102 |

115 |

88.9 |

63 |

4-16 |

135 |

100 |

76 |

4-19 |

|

40 |

473 |

150 |

110 |

84 |

4-Φ18 |

114 |

125 |

98.4 |

73 |

4-16 |

140 |

105 |

81 |

4-19 |

|

50 |

488 |

165 |

125 |

99 |

4-Φ18 |

124 |

150 |

1207 |

92.1 |

4-18 |

155 |

120 |

96 |

4-19 |

|

65 |

561 |

185 |

145 |

118 |

8-Φ18 |

145 |

180 |

139.7 |

104.8 |

4-18 |

175 |

140 |

116 |

4-19 |

|

80 |

586 |

200 |

160 |

132 |

8-Φ18 |

165 |

190 |

152.4 |

127 |

4-18 |

185 |

150 |

126 |

8-19 |

|

100 |

607 |

220 |

180 |

156 |

8-Φ18 |

194 |

230 |

190.5 |

157.2 |

8-18 |

210 |

175 |

151 |

8-19 |

|

125 |

668 |

250 |

210 |

184 |

8-Φ18 |

194 |

255 |

215.9 |

185.7 |

8-22 |

250 |

210 |

182 |

8-23 |

|

150 |

693 |

285 |

240 |

211 |

8-Φ22 |

229 |

280 |

241.3 |

215.9 |

8-22 |

280 |

240 |

212 |

8-23 |

|

200 |

768 |

340 |

295 |

266 |

12-Φ22 |

243 |

345 |

298.5 |

269.9 |

8-22 |

330 |

290 |

262 |

12-23 |

|

250 |

901 |

405 |

355 |

319 |

12-Φ26 |

297 |

405 |

362 |

323.8 |

12-26 |

400 |

355 |

324 |

12-25 |

|

300 |

921 |

460 |

410 |

370 |

12-Φ26 |

338 |

485 |

431.8 |

381 |

12-26 |

445 |

400 |

368 |

16-25 |

|

350 |

1062 |

520 |

470 |

429 |

16-Φ29 |

400 |

535 |

476.3 |

412.8 |

12-30 |

490 |

445 |

413 |

16-25 |

|

400 |

1117 |

580 |

525 |

480 |

16-Φ30 |

400 |

595 |

539.8 |

469.9 |

16-30 |

560 |

510 |

475 |

16-27 |

|

450 |

1255 |

640 |

585 |

548 |

20-Φ30 |

520 |

635 |

577.9 |

533.4 |

16-33 |

620 |

565 |

530 |

20-27 |

|

500 |

1282 |

715 |

650 |

609 |

20-Φ33 |

600 |

700 |

635 |

584.2 |

20-33 |

675 |

620 |

585 |

20-27 |