Lugged Butterfly Valve Manufacturer in China: Quality and Reliability

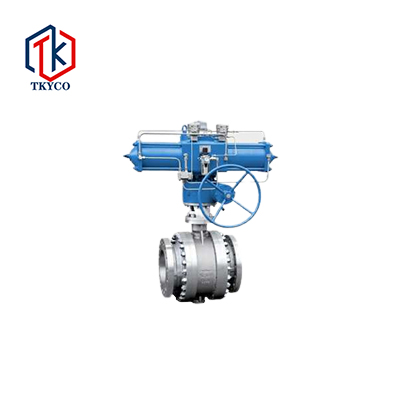

When it comes to reliable flow control, I know that the lugged butterfly valve is a top choice for many industries. As a professional in valve solutions, I understand the importance of durability and efficiency in high-pressure environments. Manufactured in China, our lugged butterfly valves are crafted from high-quality materials, ensuring they withstand rigorous operational demands. With a unique lug design that allows for easy installation and maintenance, these valves provide excellent sealing capabilities, making them perfect for various applications. I pride myself on being a reliable partner who understands the specific needs of B2B purchasers. Investing in our valves means you’re choosing precision engineering backed by rigorous quality control. Let’s work together to enhance your operations with our robust lugged butterfly valves, specifically designed for professionals like you who demand the best in performance and reliability. Reach out to learn how we can support your needs today!

Lugged Butterfly Valve Is The Best Now Trending

The lugged butterfly valve is rapidly gaining traction in various industrial applications due to its superior performance and design efficiency. As industries strive for reliability and cost-effectiveness, this valve type stands out with its unique lug connection feature that allows for easy installation and maintenance. Unlike traditional valves, the lugged design enables the valve to be bolted directly to the pipeline, making it suitable for dead-end services and ensuring minimal downtime during service operations. Moreover, its lightweight construction and compact design make the lugged butterfly valve an excellent choice for space-constrained environments without compromising on flow control abilities. This versatility extends its application across diverse sectors, including water treatment, oil and gas, and HVAC systems. The trending popularity of this valve can also be attributed to advancements in manufacturing technologies that ensure heightened durability, improved sealing, and enhanced operational efficiency, resulting in lower lifecycle costs for users. As global demand for innovative solutions grows, investing in lugged butterfly valves can provide industries with the competitive edge needed to thrive in a rapidly evolving market. The continued development and integration of these valves are expected to play a significant role in optimizing operations, promoting sustainability, and ensuring safety across various applications. Now is the ideal time for importers and distributors to explore the benefits of incorporating lugged butterfly valves into their product offerings.

Lugged Butterfly Valve Is The Best Now Trending

| Dimension | Material | Temperature Range (°C) | Pressure Rating (MPa) | Applications |

|---|---|---|---|---|

| 2 inch | Cast Iron | -10 to 80 | 1.6 | Water Supply, HVAC |

| 4 inch | Stainless Steel | -20 to 150 | 2.5 | Chemical Processing, Food |

| 6 inch | Brass | -10 to 100 | 1.0 | Oil & Gas, Water Treatment |

| 8 inch | PVC | 0 to 60 | 0.6 | Irrigation, Wastewater |

Related Products