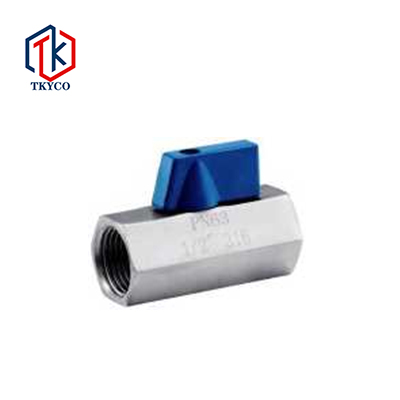

China Manufacturer of Shut Off Valve Leaking Solutions and Repairs

If you’re dealing with a shut off valve leaking issue, I understand how crucial it is to find a reliable solution that prevents further complications. As a manufacturer based in China, I pride myself on providing high-quality valves that are designed to perform under pressure while ensuring durability and longevity. Our shut off valves undergo stringent testing to meet industry standards and are available in various sizes to suit your specific needs. I’ve seen firsthand how a leaky valve can disrupt operations, leading to increased costs and downtime. That’s why I’m committed to offering products that not only solve your immediate problems but also provide long-term reliability. By choosing our valves, you’re not just purchasing a product; you’re investing in peace of mind. Get in touch to discover how our shut off valves can make a difference for your business and help you maintain seamless operations.

Shut Off Valve Leaking Supplier For the Current Year

When sourcing shut-off valves, understanding the intricacies of leakage issues is crucial for buyers in various industries. In the current year, the focus on quality and reliability in valve manufacturing has heightened, as leaks can result in costly downtime and safety hazards. As global suppliers adapt to stricter regulatory standards and technological advancements, selecting the right supplier is vital to ensure seamless operations and compliance with industry norms. Innovative designs and premium materials have emerged as key factors in minimizing leakage risks in shut-off valves. Suppliers are not only focusing on durability but also on improving the performance metrics of their products. Buyers are encouraged to inquire about the latest advancements in valve technology, including robust sealing mechanisms and advanced manufacturing processes. Collaborating with suppliers who prioritize quality control measures can help procure products that meet stringent performance standards. In a competitive marketplace, transparent communication and support from suppliers play a significant role in fostering strong partnerships. Global buyers should look for suppliers that offer comprehensive after-sales support and are willing to provide insights into product maintenance and best practices. By aligning with reliable suppliers, businesses can enhance their operational efficiency while mitigating the risks associated with valve leaks, ensuring a smooth and sustainable workflow.

Shut Off Valve Leaking Supplier For the Current Year

| Supplier ID | Supplier Name | Contact Person | Location | Leak Types | Rating |

|---|---|---|---|---|---|

| 001 | Supplier A | John Doe | New York, USA | Minor, Severe | 4.5 |

| 002 | Supplier B | Jane Smith | California, USA | Minor | 4.0 |

| 003 | Supplier C | Emily Johnson | Texas, USA | Severe | 4.8 |

| 004 | Supplier D | Michael Brown | Florida, USA | Minor, Moderate | 4.3 |

Related Products