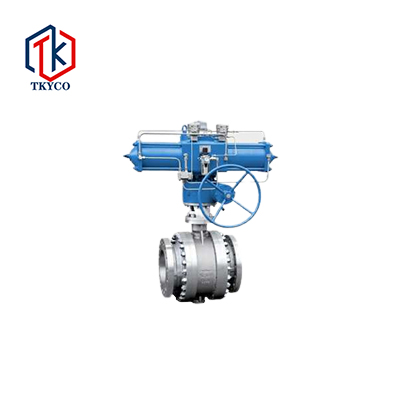

Ss Butterfly Valve Manufacturer in China: Quality & Reliability Guaranteed

When it comes to reliable performance in fluid control, I highly recommend the Ss Butterfly Valve. As a trusted option in the market, this valve combines durability with efficiency. Manufactured in China, I appreciate how these valves are designed to handle various media under different conditions, ensuring a long service life. The innovative design allows for rapid opening and closing, which minimizes fluid resistance and enhances overall operational efficiency. Each valve undergoes strict quality control to meet international standards, guaranteeing you receive only the best. What truly sets this Ss Butterfly Valve apart is its availability in various sizes, making it suitable for an array of industrial applications. If you are in search of a manufacturer that prioritizes quality and reliability, this product is a great choice for your B2B needs. Let’s connect and explore how this product can meet your specific requirements.

Ss Butterfly Valve For the Current Year Leads the Global Market

In the evolving landscape of industrial valve technology, the stainless steel butterfly valve has emerged as a frontrunner in meeting the demands of various industries globally. This year, the Ss butterfly valve is not only enhancing operational efficiency but also ensuring durability and reliability for critical applications. Its streamlined design allows for optimal flow control and minimal pressure drop, making it an ideal choice for fluid handling systems. The increasing adoption of these valves can be attributed to their versatility and the advancements in manufacturing that have improved their performance metrics. Industries ranging from water treatment to oil and gas are recognizing the potential of the stainless steel butterfly valve to maintain operational integrity while adhering to stringent safety standards. Furthermore, the ongoing push for sustainability has led to an uptick in the use of these valves, as they contribute to energy savings and reduced environmental impact. As the global market continues to grow, stakeholders should consider integrating stainless steel butterfly valves into their systems to enhance performance and ensure compliance with industry standards. The reliability and efficiency offered by these valves make them a strategic choice, ensuring that companies remain competitive in today’s fast-paced industrial environment.

Ss Butterfly Valve For the Current Year Leads the Global Market

| Region | Market Share (%) | Growth Rate (%) | Applications | Material |

|---|---|---|---|---|

| North America | 30 | 5 | Water Supply, Oil & Gas | Stainless Steel |

| Europe | 25 | 4.5 | Chemical Processing, HVAC | Bronze |

| Asia Pacific | 35 | 7 | Wastewater Treatment, Power Generation | Carbon Steel |

| Latin America | 5 | 3 | Mining, Agriculture | Alloy Steel |

| Middle East & Africa | 5 | 4 | Oil & Gas, Water Desalination | Duplex Stainless Steel |

Related Products