Top China Manufacturer of Quality Stainless Ball Valves for Your Needs

When I think about reliable and durable solutions for fluid control, the stainless ball valve immediately comes to mind. Sourced directly from reputable manufacturers in China, these valves offer exceptional strength and resistance to corrosion, making them ideal for a variety of industries. The precision engineering ensures smooth operation and longevity, which is crucial for minimizing downtime and maintenance costs. I know how important it is for businesses to have components that perform under pressure, and that's why I highly recommend our stainless ball valves. They come in various sizes and specifications to fit your exact needs. Whether you're in chemical processing, water treatment, or any other sector, these valves are designed to deliver top-notch performance. Partnering with experienced manufacturers in China means you're getting quality you can trust without compromising on cost. Elevate your projects with our stainless ball valves today to experience reliability and efficiency like never before.

Stainless Ball Valve Pioneers in the Field Your Trusted OEM Partner

In the ever-evolving field of valve manufacturing, stainless ball valves have emerged as a cornerstone of reliability and efficiency. As a leader in the industry, we recognize the vital role that these valves play across various sectors, including oil and gas, water treatment, and food processing. Given their robust design and corrosion resistance, stainless ball valves ensure optimal performance, even in the most demanding environments. Our commitment to quality and innovation positions us as a trusted partner for global procurement professionals seeking to enhance their operations with superior products. Collaborating with an OEM partner dedicated to excellence can significantly impact your supply chain efficiency. Our advanced manufacturing techniques and stringent quality control processes ensure that each valve meets international standards, providing peace of mind when it comes to reliability and safety. We offer tailored solutions that align with your specific needs, while our experienced team is dedicated to delivering unparalleled support throughout the procurement process. By choosing us as your OEM partner, you gain access to cutting-edge technology and a wealth of industry knowledge that can drive your business forward. In today's competitive landscape, making informed decisions is crucial. Our stainless ball valves are engineered for longevity and performance, which translates to reduced maintenance costs and enhanced operational reliability. As we continue to innovate and expand our product line, we aim to remain at the forefront of the industry, ensuring that our partners can rely on us for both current and future demands. Explore the advantages of working with a pioneer in stainless ball valve manufacturing and take your procurement strategy to the next level.

Stainless Ball Valve Pioneers in the Field Your Trusted OEM Partner

| Product Type | Material | Size (inch) | Pressure Rating (PSI) | Connection Type | Applications |

|---|---|---|---|---|---|

| Full Port Ball Valve | Stainless Steel 304 | 1" | 150 | Threaded | Water, Oil, Gas |

| Reduced Port Ball Valve | Stainless Steel 316 | 1.5" | 200 | Flanged | Chemical Processing |

| Three-Way Ball Valve | Stainless Steel 316L | 2" | 300 | Socket Weld | HVAC Systems |

| Floating Ball Valve | Stainless Steel 304 | 3" | 150 | Bevel Gear | Water Treatment |

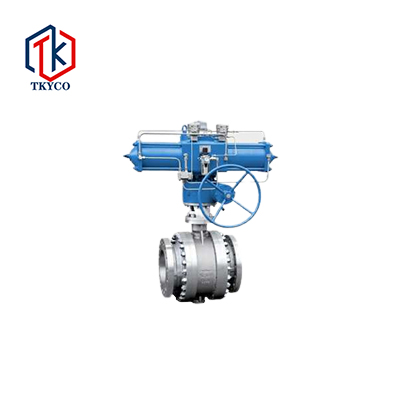

| High-Pressure Ball Valve | Stainless Steel 316 | 4" | 600 | Flanged | Oil & Gas |

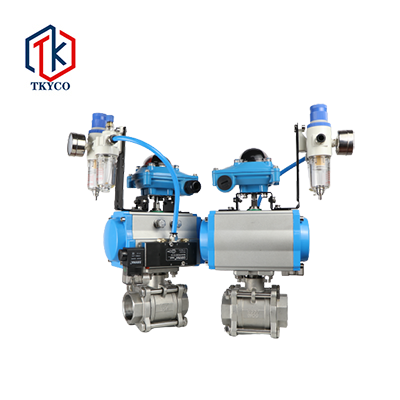

Related Products