China Manufacturer of Ball and Butterfly Valves - Quality Solutions

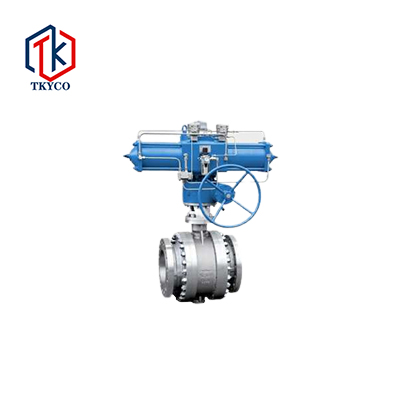

When it comes to sourcing reliable Ball and Butterfly Valves, I understand that quality and performance is paramount for your operations. We specialize in manufacturing these critical components right here in China, where advanced technology meets skilled craftsmanship. Our valves are designed to offer exceptional durability and leak-proof performance, ensuring that your systems run smoothly. I’m proud to say that our manufacturing practices adhere to international standards, making our products suitable for various industrial applications. Whether you need valves for chemical processing, water treatment, or HVAC systems, we can customize them to meet your specific needs. By choosing our valves, you are not only getting high-quality products but also a partner who understands the intricacies of your business. Let’s connect to discuss how our Ball and Butterfly Valves can help optimize your operations and contribute to your success in the competitive market.

Ball And Butterfly Valves Industry Giant Supplies the World\u2019s Top Brands

In the rapidly evolving world of industrial valves, the demand for high-quality, reliable products has never been more critical. Leading manufacturers are stepping up to meet the needs of global buyers by offering an extensive range of ball and butterfly valves, designed for various applications across diverse industries. These valves are renowned for their exceptional durability, ease of operation, and efficiency, making them indispensable in sectors such as oil and gas, water treatment, and chemical processing. The importance of sourcing these components from reputable suppliers cannot be overstated. Global procurement professionals are increasingly focused on quality assurance and operational efficiency. By partnering with industry giants that specialize in advanced manufacturing techniques and rigorous testing protocols, businesses can ensure they receive products that not only meet but exceed international standards. This commitment to excellence translates into reduced downtime, enhanced productivity, and ultimately, greater profitability for end-users. Furthermore, sustainable practices are becoming central to procurement strategies. The leading valve manufacturers are integrating eco-friendly materials and practices into their production processes, addressing the growing demand for environmentally responsible products. By choosing suppliers that prioritize sustainability, global buyers can align with corporate social responsibility initiatives and contribute to a greener future while still fulfilling their operational requirements. As the landscape of the valve industry continues to evolve, staying informed about the latest innovations and sustainable practices will be essential for maintaining a competitive edge.

Ball And Butterfly Valves Industry Giant Supplies the World’s Top Brands

| Valve Type | Material | Size (inches) | Application | Pressure Rating (psi) |

|---|---|---|---|---|

| Ball Valve | Stainless Steel | 1.5 | Water Supply | 150 |

| Butterfly Valve | PVC | 2 | Chemical Processing | 200 |

| Ball Valve | Brass | 3 | HVAC Systems | 300 |

| Butterfly Valve | Ductile Iron | 4 | Water Distribution | 250 |

Related Products