Top China Manufacturer of Reliable Boiler Check Valves for Your Needs

Our Boiler Check Valve is essential for reliable operation in any heating system. As a leading manufacturer in China, we pride ourselves on delivering high-quality, durable components that ensure maximum efficiency and safety. I’ve found that our check valves not only prevent backflow but also enhance system performance, making them a crucial addition to your boiler setup. Crafted from top-grade materials, these valves withstand high pressure and temperatures, guaranteeing longevity. We understand the challenges faced by B2B purchasers, so we ensure our products meet international standards while remaining cost-effective. When you choose our Boiler Check Valve, you’re not just investing in a component; you're investing in reliability and peace of mind. Connect with me today to explore how our solutions can meet your specific needs and improve your operations.

Boiler Check Valve Your Trusted OEM Partner Where Service Meets Innovation

When it comes to the critical components of a boiler system, the check valve stands out as an essential part that ensures both efficiency and safety. As an OEM partner, we are dedicated to providing innovative solutions tailored to meet the unique needs of our global clients. Our check valves not only comply with international standards but are also designed with the latest technology to enhance durability and performance. In the rapidly evolving industrial landscape, staying ahead means embracing innovation without compromising on service quality. We pride ourselves on our ability to combine state-of-the-art manufacturing processes with a customer-centric approach. This commitment allows us to deliver products that solve real-world challenges faced by procurement specialists in various sectors, from energy to manufacturing. Our check valves are engineered for optimal flow control, preventing backflow and ensuring systems run smoothly, which is crucial for maintaining operational integrity. Partnering with us means gaining access to a wealth of expertise and an extensive product range. We understand the importance of reliability and responsiveness in today’s global marketplace, and our team is committed to providing excellent support from the initial inquiry through to after-sales service. Choose us as your trusted OEM partner, and experience the perfect blend of innovative products and exceptional service that meets the demands of your industry.

Boiler Check Valve Your Trusted OEM Partner Where Service Meets Innovation

| Feature | Description | Advantages | Applications |

|---|---|---|---|

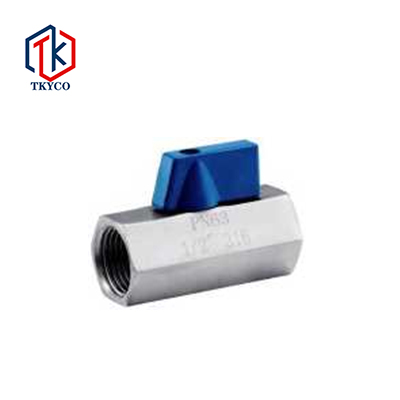

| Material | High-grade stainless steel | Corrosion-resistant, durable | Industrial boilers, HVAC systems |

| Pressure Rating | Up to 300 PSI | Suitable for high-pressure applications | Power plants, manufacturing processes |

| Temperature Range | -20°C to 150°C | Wide operational range | Hot water systems, steam generation |

| Connection Type | Flanged and threaded options | Versatility in installation | Any boiler or plumbing system |

| Certification | API 598 | Meets industry standards | Safety and reliability in operations |

Related Products