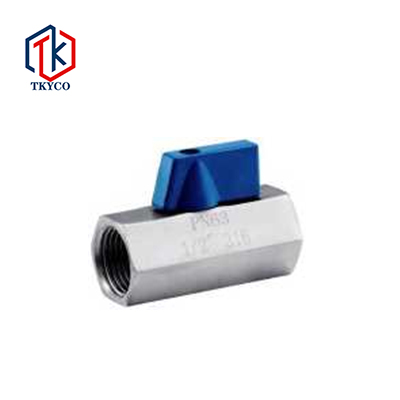

Top Cast Steel Ball Valve Manufacturer in China for Quality Solutions

When it comes to reliable flow control solutions, I always trust cast steel ball valves for their durability and performance. Sourced directly from trusted Chinese manufacturers, these valves provide exceptional sealing and longevity even in the most demanding environments. I’ve seen how they withstand high pressure and temperature, making them ideal for a range of industrial applications. The precision-engineered design ensures smooth operation, reducing wear and tear over time. For businesses like mine, investing in quality components is crucial, and I’ve found that Chinese manufacturers often deliver outstanding value without compromising on quality. Plus, with various sizes and configurations available, it's easy to find the right fit for any project. I strongly recommend considering cast steel ball valves if you’re seeking high performance and reliable operation. You won’t just be getting a product; you’ll be investing in peace of mind.

Cast Steel Ball Valve Factory in 2025

As we approach 2025, the demand for cast steel ball valves is expected to surge globally, driven by advancements in industrial applications across various sectors. The robust features of cast steel ball valves, including their excellent durability, resistance to high pressure, and ability to handle extreme temperatures, make them a preferred choice for many manufacturers. The ongoing transformation in energy, oil and gas, and water treatment industries is predicted to increase the applications of these valves significantly, presenting a lucrative opportunity for suppliers. In response to this growing demand, manufacturers are focusing on innovation and sustainability within their production processes. Embracing advanced technologies such as automation and IoT integration, factories are streamlining operations to enhance efficiency and reduce waste. Moreover, the commitment to quality assurance and compliance with international standards ensures that these products not only meet but exceed customer expectations. For procurement professionals looking to source high-quality cast steel ball valves, the emphasis should be on partnering with manufacturers that demonstrate a strong track record of reliability and customer service. As we move forward, maintaining competitive pricing while ensuring superior product offerings will be crucial in navigating the global market landscape. By staying informed about market trends and technological advancements, buyers can make informed decisions, ultimately leading to successful procurement strategies in the years to come.

Cast Steel Ball Valve Factory in 2025

| Dimension | Material | Pressure Rating (ANSI) | Application | Certification |

|---|---|---|---|---|

| 1/2 inch | ASTM A216 WCB | 150 | Water & Gas | ISO 9001 |

| 3/4 inch | ASTM A216 WCB | 150 | Oil & Gas | API 6D |

| 1 inch | ASTM A216 WCB | 150 | Chemical Processing | CE |

| 2 inch | ASTM A216 WCB | 150 | Pharmaceuticals | ASME |

| 3 inch | ASTM A216 WCB | 150 | HVAC Systems | NACE |

Related Products