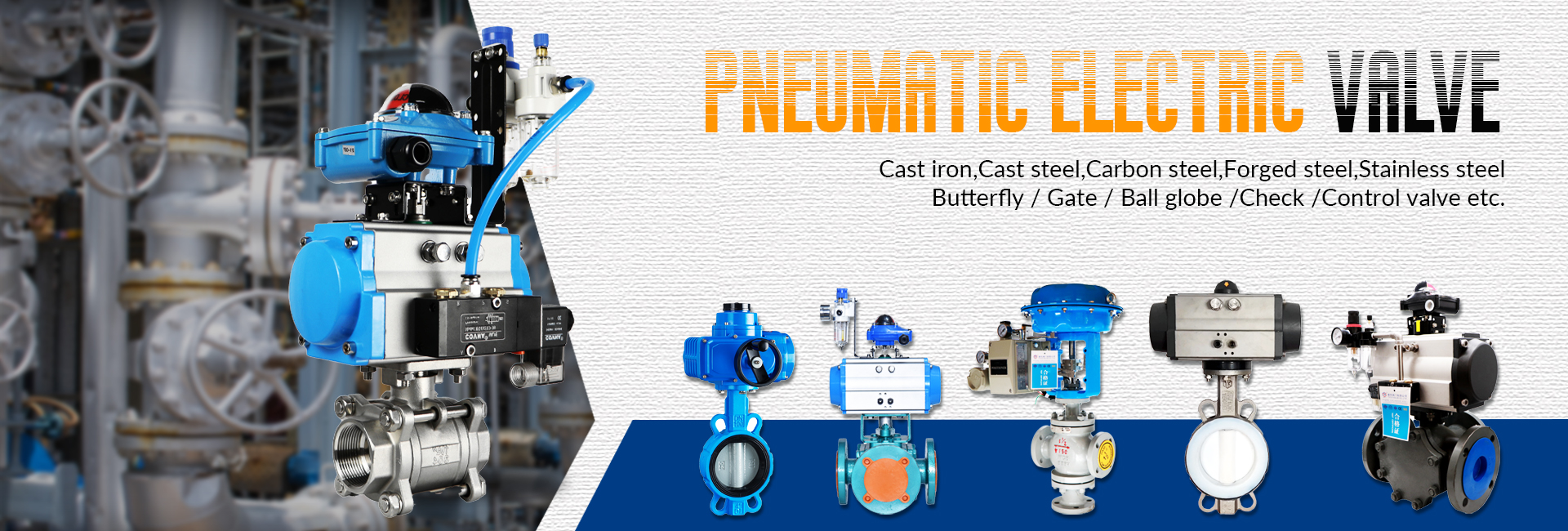

Electric Actuated Gate Valve Manufacturer in China - Quality Assurance

When it comes to enhancing your industrial processes, the Electric Actuated Gate Valve is a game changer. I’ve seen firsthand how these valves offer precise control and reliability, essential for smooth operation in various applications. Sourced directly from a reputable manufacturer in China, our products guarantee durability and efficiency that meet international standards. With an electric actuator, you can expect seamless operation without the hassle of manual adjustments, saving both time and labor costs. Whether you’re in oil and gas, water treatment, or any other industry, this valve is designed to deliver optimal performance. The robust construction ensures it can handle high pressures and abrasive materials, making it a reliable choice for your needs. Investing in our Electric Actuated Gate Valve not only improves your workflow but also aligns with sustainable practices. Let’s take your operations to the next level with our reliable solutions tailored for your business.

Electric Actuated Gate Valve Application Trusted by Pros

Electric actuated gate valves are becoming increasingly popular in various industries due to their reliability and efficiency. Designed to provide safe and precise flow control, these valves are trusted by professionals across sectors such as oil and gas, water treatment, and chemical processing. Their ability to automate valve operations not only enhances operational efficiency but also reduces the risk of human error, making them a valuable asset for any procurement strategy. One of the key advantages of electric actuated gate valves is their adaptability to a wide range of applications. Whether it's managing high-pressure systems or controlling the flow in complex piping networks, these valves are engineered to meet stringent industry standards. The integration of advanced automation technologies ensures that they can be seamlessly integrated into existing systems, providing users with enhanced monitoring and control capabilities. For global buyers, investing in electric actuated gate valves means prioritizing not only performance but also long-term reliability. Professionals in the field recommend choosing valves from manufacturers who emphasize quality and innovation, as these will ultimately lead to reduced maintenance costs and increased operational uptime. With a growing demand for advanced valve solutions in diverse markets, understanding the benefits and applications of electric actuated gate valves can significantly enhance your competitive edge.

Electric Actuated Gate Valve Application Trusted by Pros

| Application Area | Valve Size (inches) | Actuator Type | Material | Pressure Rating (psi) |

|---|---|---|---|---|

| Water Treatment | 4 | Electric | Stainless Steel | 150 |

| Oil & Gas | 6 | Electric | Carbon Steel | 300 |

| Chemical Processing | 8 | Electric | PVC | 150 |

| Mining | 10 | Electric | Ductile Iron | 250 |

| Power Generation | 12 | Electric | Alloy Steel | 600 |

Related Products