Top Globe Stop Check Valve Manufacturer in China – Quality Guaranteed

As a seasoned professional in the valve industry, I understand the importance of reliable components like the Globe Stop Check Valve. Manufactured in China, this product combines durability and performance, making it the perfect choice for various applications. I’ve seen firsthand how this valve helps manage flow and prevent backflow, ensuring optimal system efficiency. Ideal for both industrial and commercial uses, its sturdy design reduces the risk of leaks and failures, which is crucial for maintaining safety and productivity. With a focus on quality, our manufacturing process adheres to stringent standards to provide you with a reliable solution. When you choose the Globe Stop Check Valve, you’re investing in longevity and performance that truly meets your business needs. If you’re in search of a trustworthy manufacturer, look no further, as our commitment to excellence guarantees your satisfaction. Reach out today to learn how we can support your operations with this essential product.

Globe Stop Check Valve Application Pioneers in the Field

In the ever-evolving landscape of industrial applications, the importance of reliable mechanisms cannot be overstated. The globe stop check valve stands out as a vital component in numerous sectors, offering both efficiency and safety. Its unique design allows for precise control of flow direction, making it indispensable in applications where backflow prevention is critical. As industries globally strive for enhanced performance, these valves have emerged as pioneers, innovating the way fluid dynamics are managed. With a growing demand for advanced solutions, the globe stop check valve has proven its versatility across various fields, including oil and gas, water treatment, and chemical processing. Its ability to withstand extreme pressures and temperatures ensures longevity and reduces maintenance costs significantly. Understanding the specific needs of diverse industries, manufacturers are continuously investing in research and development to create valves that meet rigorous international standards, cater to unique regional requirements, and adapt to advancing technologies. For global procurement professionals, selecting the right globe stop check valve means not just acquiring a product, but investing in a solution that guarantees operational efficiency and safety. As awareness about the importance of quality and reliability grows, aligning with a leader in valve technology becomes essential. By focusing on innovative designs and sustainable practices, the industry is poised for future advancements, ensuring that the globe stop check valve remains at the forefront of fluid control technology.

Globe Stop Check Valve Application Pioneers in the Field

| Application Area | Medium | Temperature Range | Pressure Rating | Material |

|---|---|---|---|---|

| Water Supply Systems | Water | 0°C to 60°C | PN16 | Cast Iron |

| Oil and Gas | Crude Oil | -20°C to 80°C | ANSI Class 150 | Stainless Steel |

| Chemical Processing | Acids and Bases | -10°C to 90°C | PN40 | PVC |

| Power Generation | Steam | 150°C to 300°C | ANSI Class 300 | Carbon Steel |

| HVAC Systems | Air | -20°C to 50°C | Low Pressure | Aluminum |

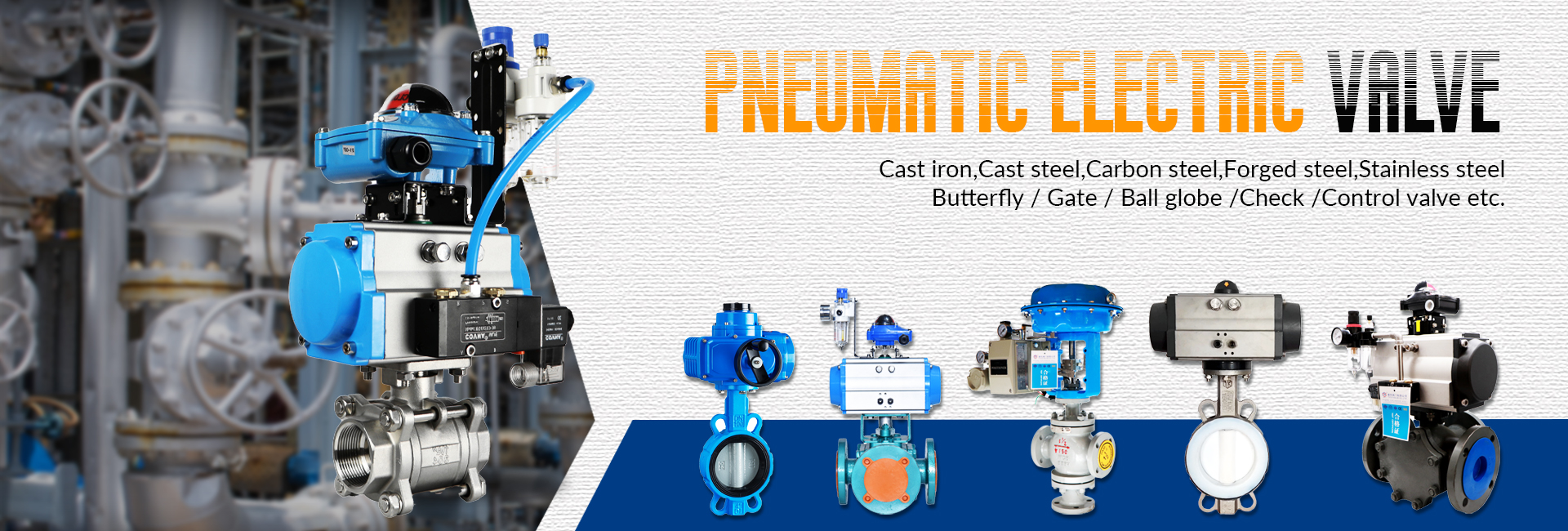

Related Products