Top China Manufacturer of Industrial Butterfly Valves for Your Needs

When sourcing high-quality industrial butterfly valves, I know how crucial it is to find a reliable manufacturer. That's why I choose to partner with top-tier suppliers from China, known for their precision engineering and durability. Our industrial butterfly valves are designed to handle various applications, offering exceptional performance and longevity. With a wide range of sizes and specifications, these valves ensure optimal flow control in your systems. I personally value the attention to detail in the manufacturing process, which guarantees that each valve meets international standards. The feedback from those who have used our products speaks volumes—outstanding reliability and efficiency! Whether you're in the oil and gas industry or managing a water treatment facility, you’ll find that our valves are up to the task. Trust me, you won't be disappointed in the quality we provide. Reach out to learn more about how our industrial butterfly valves can meet your specific needs!

Industrial Butterfly Valve Stands Out Industry Giant

In the ever-evolving industrial landscape, selecting the right components for fluid control systems is critical to operational efficiency. Among various options available, the industrial butterfly valve has emerged as an exemplary solution, capturing the attention of procurement professionals globally. With its unique design features, including a lightweight structure and quick installation capabilities, the butterfly valve is not only cost-effective but also enhances system reliability and performance. The standout qualities of this valve type stem from its ability to provide reliable shut-off and throttling control across diverse applications. Its design allows for minimal pressure drops, ensuring energy conservation while maintaining effective flow management. Moreover, advancements in materials and manufacturing technologies have significantly improved the durability and lifespan of these valves, making them suitable for demanding environments. As industries worldwide seek to optimize their processes, the industrial butterfly valve represents a strategic investment that aligns with both performance and sustainability goals. As global procurement trends increasingly lean towards innovative and efficient solutions, the industrial butterfly valve serves as a crucial component in the quest for operational excellence. By integrating these valves into fluid control systems, organizations can achieve significant improvements in efficiency and cost savings, positioning themselves for success in a competitive market. Investing in such reliable components not only enhances productivity but also contributes to long-term sustainability efforts, echoing the industry's commitment to a greener future.

Industrial Butterfly Valve Stands Out Industry Giant

| Feature | Specification | Application | Material |

|---|---|---|---|

| Positive sealing | Up to 10 bar | Chemical processing | Stainless steel |

| Low torque requirement | 30% less than traditional valves | Water treatment | Cast iron |

| Compact design | Size reduction by 20% | HVAC systems | PVC |

| Replaceable seats | Standardized sizes | Oil and gas | Bronze |

| High flow capacity | Up to 4000 L/min | Agricultural irrigation | EPDM |

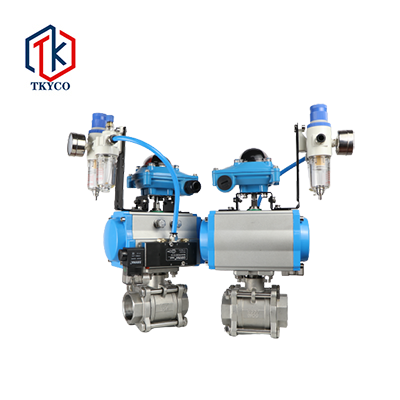

Related Products