Top China Manufacturer of Water Butterfly Valves for Optimal Performance

When searching for a reliable solution for fluid control, I find the Water Butterfly Valve stands out for its efficient design and durability. Sourced from a leading manufacturer in China, this valve is engineered to handle varying flow pressures while maintaining peak performance. The lightweight structure makes installation a breeze, and it offers excellent sealing capabilities to prevent leaks, ensuring peace of mind. What really sets our Water Butterfly Valve apart is its versatility—suitable for a range of applications from water treatment to industrial processes. I appreciate the quality materials used in its construction, providing long-lasting service even in demanding environments. Plus, working directly with a manufacturer offers the benefit of customization, allowing me to meet specific project needs effectively. With our Water Butterfly Valve, I can confidently enhance operational efficiency and achieve reliable performance in every task. Let’s connect to explore how this product can benefit your operations.

Water Butterfly Valve Is The Best Leads the Global Market

In today's industrial landscape, the water butterfly valve has emerged as a pivotal component, catering to various applications across diverse sectors. Renowned for its efficient flow regulation and space-saving design, this valve type minimizes pressure loss while offering robust performance. As global demand for reliable and durable water management solutions rises, the superior engineering of water butterfly valves positions them as the ideal choice for both large-scale projects and smaller installations. The innovative design and advanced features of modern water butterfly valves give them a competitive edge in the global market. These valves facilitate seamless operation, with options for automation enhancing functionality. Their lightweight construction combined with resistance to corrosion makes them suitable for challenging environments, such as wastewater treatment facilities and irrigation systems. Furthermore, easy maintenance and installation contribute to reduced operational costs, making them attractive to procurement managers seeking long-term solutions. As industries continue to evolve, ensuring the reliability and efficiency of water flow systems is crucial. With unmatched performance, durability, and cost-effectiveness, water butterfly valves are setting new standards and leading the way in the global market. For procurement professionals looking to invest in high-quality components, choosing the right valves can significantly impact operational efficiency and service reliability. This makes water butterfly valves an indispensable component for future-ready industrial applications.

Water Butterfly Valve Is The Best Leads the Global Market

| Region | Market Share (%) | Growth Rate (2023) | Main Applications | Key Trends |

|---|---|---|---|---|

| North America | 25 | 5% | Water Treatment, Power Generation | Increasing automation |

| Europe | 30 | 4% | Chemical Processing, HVAC | Sustainability focus |

| Asia-Pacific | 35 | 6% | Mining, Oil & Gas | Rapid industrialization |

| Latin America | 5 | 3% | Agriculture, Water Supply | Investment in infrastructure |

| Middle East & Africa | 5 | 4.5% | Desalination, Oil Refineries | Emerging market growth |

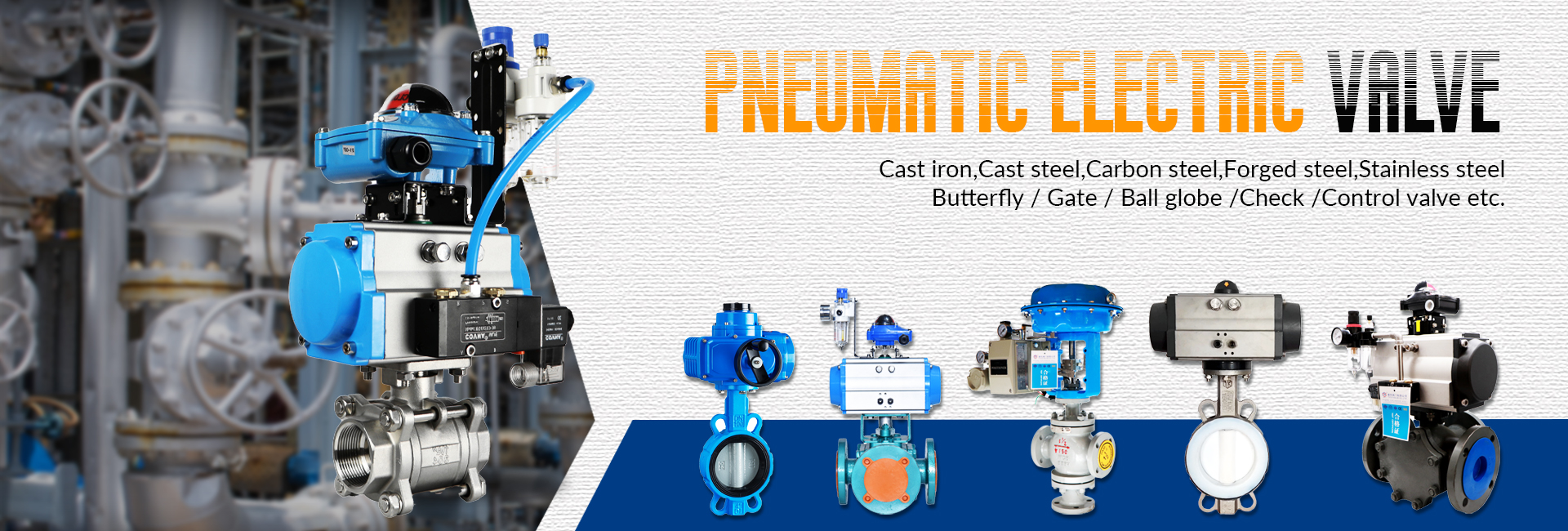

Related Products