8 Butterfly Valve Manufacturer in China: Quality & Reliability Guaranteed

When it comes to high-quality butterfly valves, I trust our 8 Butterfly Valve – meticulously engineered for optimal performance. Sourced directly from a leading manufacturer in China, these valves are designed to assure durability and efficiency in diverse applications. I’ve seen firsthand how their robust construction holds up even in tough environments, making them a reliable choice for various industries. What I appreciate most is the precision of each valve, allowing for seamless flow control and minimal leakage. With competitive pricing and exceptional customer service, the support from the manufacturer has been invaluable for my projects. If you’re seeking a cost-effective solution without compromising on quality, this is the valve you need. Let’s elevate your operations with a product that stands the test of time. I’m confident that the 8 Butterfly Valve will meet all your expectations, making it an excellent investment for your business.

8 Butterfly Valve Application Trusted by Pros

Butterfly valves are essential components in many fluid control applications, providing efficient flow regulation and shut-off capabilities. These valves are favored by professionals across diverse industries due to their lightweight design, compact size, and simple installation. In this post, we will explore eight trusted applications of butterfly valves that highlight their versatility and reliability. The first application is in water treatment plants, where butterfly valves control the flow of water through various stages of purification, ensuring optimal performance and safety. Another vital use is in HVAC systems, where these valves manage air circulation and temperature, contributing to energy efficiency and comfort in buildings. In the oil and gas sector, butterfly valves are deployed to regulate the flow of hydrocarbons, requiring robust materials to withstand harsh conditions. Moreover, they play a critical role in chemical processing, allowing for precise control over corrosive fluids. Additionally, butterfly valves are prevalent in food and beverage processing, where hygiene and compliance with sanitary standards are paramount. Their ease of cleaning and minimal dead space make them ideal for this industry. In power generation, especially in cooling systems, butterfly valves facilitate efficient water flow, enhancing plant performance. Lastly, they are essential in mining operations for handling slurry and tailings, ensuring controlled discharge and minimal environmental impact. These diverse applications illustrate why butterfly valves are a trusted choice for professionals seeking reliable solutions in fluid management.

8 Butterfly Valve Applications Trusted by Pros

| Application Area | Valve Size (Inches) | Material | Pressure Rating (PSI) | Temperature Range (°F) |

|---|---|---|---|---|

| Water Treatment | 2 | Stainless Steel | 150 | 32 - 140 |

| Oil & Gas | 4 | Carbon Steel | 300 | -20 - 250 |

| HVAC Systems | 3 | Aluminum | 200 | 40 - 200 |

| Chemical Processing | 6 | PVC | 150 | 32 - 140 |

| Mining | 8 | Ductile Iron | 250 | -40 - 300 |

| Power Generation | 10 | Cast Iron | 350 | 0 - 400 |

| Food & Beverage | 1.5 | 316L Stainless Steel | 150 | -4 - 180 |

| Pulp & Paper | 5 | FRP | 200 | 32 - 150 |

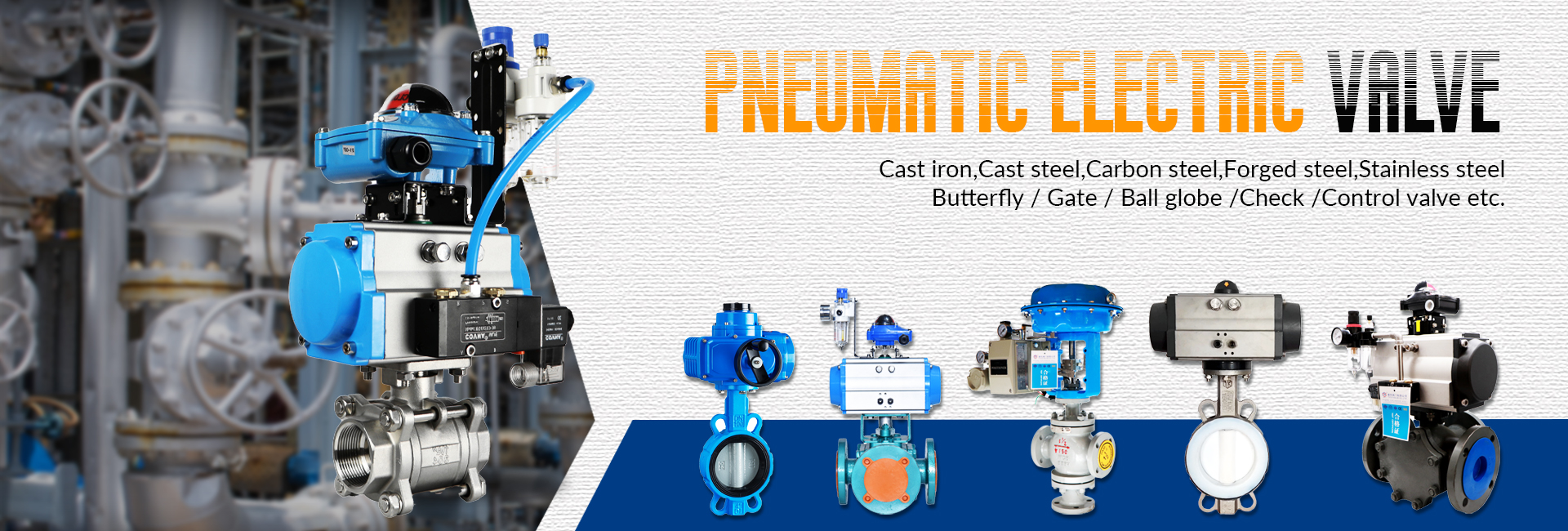

Related Products