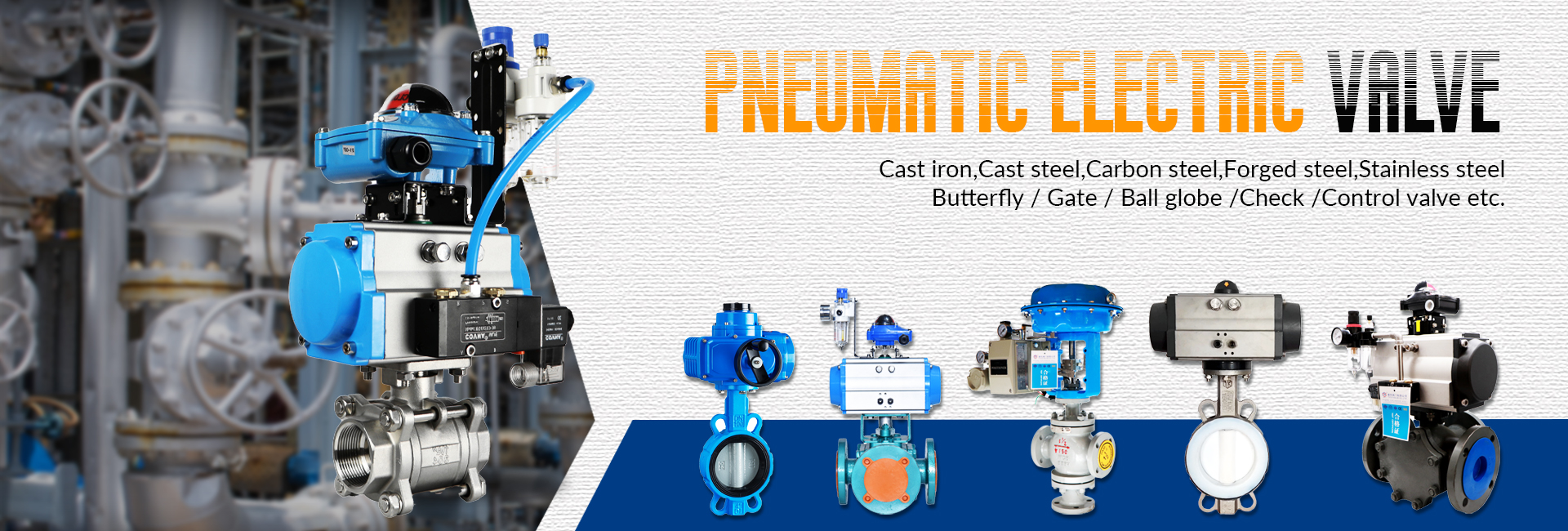

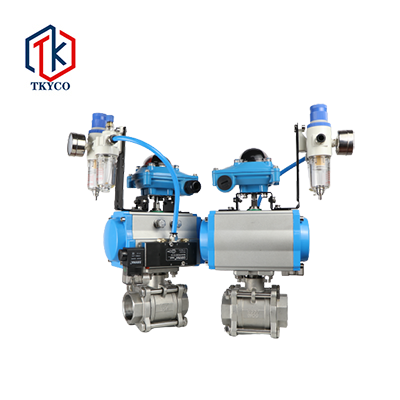

Cs Globe Valve Manufacturer in China: Quality and Reliability Unmatched

As a buyer in need of reliable valve solutions, I value quality and durability. The CS Globe Valve, designed for precision control in various applications, stands out to me. Being manufactured in China, I know that these valves are crafted with advanced technology and materials to ensure optimal performance. I appreciate how the CS Globe Valve offers excellent flow regulation, making it perfect for industries like water treatment, oil, and gas. With a robust construction, it withstands demanding environments, which is a big plus for me. Plus, with a professional manufacturer behind it, I feel confident in its reliability and longevity. And when it comes to bulk orders, I know this manufacturer can meet my business needs efficiently. Choosing the CS Globe Valve means I'm investing in performance and value, ensuring smooth operations for my projects.

Cs Globe Valve Factory Factory-Direct Excellence

When it comes to sourcing high-quality globe valves, direct factory excellence becomes a key focus for global buyers seeking reliability and performance. A reputable factory can ensure that each valve is crafted with precision, utilizing state-of-the-art technology and rigorous quality control processes. This commitment to excellence not only guarantees superior products but also fosters long-term partnerships with clients, offering them the assurance that they are investing in dependable equipment that meets their operational needs. In today's competitive market, the advantage of direct access to a valve manufacturer cannot be overstated. Bypassing middlemen allows for more transparent pricing and greater flexibility in customization. Buyers can discuss their unique requirements directly with the factory, leading to tailored solutions that optimize performance and cost-effectiveness. Additionally, working directly with the manufacturer can enhance knowledge sharing, enabling buyers to stay informed about the latest innovations and best practices in valve technology. As global industries continue to evolve, the demand for high-performance valves will rise. By collaborating with a factory dedicated to excellence, procurement professionals can ensure they are equipped with the best products to succeed. The combination of quality assurance, customization options, and direct communication lays a solid foundation for sustainable growth and operational efficiency in any sector relying on globe valves.

Cs Globe Valve Factory Factory-Direct Excellence

| Valve Type | Material | Size (inches) | Pressure Rating (psi) | Temperature Range (°F) | Application |

|---|---|---|---|---|---|

| Globe Valve A | Stainless Steel | 2 | 150 | -20 to 250 | Water Supply |

| Globe Valve B | Brass | 3 | 200 | -10 to 300 | Gas Distribution |

| Globe Valve C | Carbon Steel | 4 | 300 | 0 to 400 | Oil Pipelines |

| Globe Valve D | Cast Iron | 5 | 150 | -20 to 180 | Chemical Processing |

| Globe Valve E | PVC | 1 | 100 | 20 to 140 | Irrigation |

Related Products